ABS intlaka ziphene yokubumba

Inkcazo emfutshane:

I-resin ye-ABS (i-acrylonitrile butadiene styrene) yeyona polymer isetyenziswa kakhulu, kwaye i-ABS resin injection molding yeyona ixhaphakileyo.

I-Mestech inamava amaninzi ekubumbeni ngenaliti ye-ABS. Inkonzo yethu ABS nentlaka ziphene yokubumba kudala izinto ezisetyenziswa kumashishini ezahlukeneyo kwaye ezahlukeneyo izicelo. Izixhobo zethu zikumgangatho ophezulu ziya kuwuthatha ngokukhawuleza umsebenzi wakho ukusuka ekuqaleni ukuya esiphelweni kunye neziphumo ezisemgangathweni. Iplastiki ye-ABS resin (Acrylonitrile-Butadiene-Styrene) yeyona polymer isetyenziswa kakhulu. I-ABS yaziwa kakuhle ngeempawu zayo ezilungileyo zokuzinza, ukuqaqamba, ukuqina kunye nonyango lomphezulu ekubunjweni kwe-Injecton yinkqubo ephambili yokwenza iimveliso ze-ABS.Izinto ezibonakalayo zeProphati ye-ABS resin: Ubushushu obuphezulu: 176 ° F 80 ° C Ubushushu obuncinci: -4 ° F -20 ° C Ukuzenzekelayo kwe-Autoclave: Akukho Melting Point: 221 ° F 105 ° C Amandla oQiniso: 4,300psi Ubunzima: R110 Ukuxhathisa kwe-UV: Umbala omdaka: Ukuguquguquka okuthe ngqo : 1.04  ABS intlaka Inaliti Ukubumbela eziluncedo1.Good iipropati zombane 2.Impact ukumelana 3.Excellent ukumelana imichiza, ingakumbi asidi ezininzi ngqwabalala, glycerine, alkalis, hydrocarbon ezininzi kunye alkoholi, iityuwa ezingaphiliyo .Idibanisa amandla, ukuqina kunye nokuqina kwinto enye 5.Umgangatho ozinzileyo womthwalo 6. I-7.Ukukhanya okuzinzileyo kunye nokuqaqamba komhlaba kulungile, kulula ukupeyinta, ukufaka imibala, kunokutshizwa ngentsimbi, i-electroplating, i-welding kunye ne-bonding kunye nokunye ukusebenza kwasesekondari. 8. IABS inokwenziwa ibe yimibala eyahlukeneyo njengoko kufuneka njalo. Ukuba ukongeza ilangatye nekudodobalisa additive okanye anti-ultraviolet additive kwi ABS, inokusetyenziswa ukuvelisa amacandelo izixhobo ngaphandle okanye indawo ubushushu eliphezulu.

ABS intlaka Inaliti Ukubumbela eziluncedo1.Good iipropati zombane 2.Impact ukumelana 3.Excellent ukumelana imichiza, ingakumbi asidi ezininzi ngqwabalala, glycerine, alkalis, hydrocarbon ezininzi kunye alkoholi, iityuwa ezingaphiliyo .Idibanisa amandla, ukuqina kunye nokuqina kwinto enye 5.Umgangatho ozinzileyo womthwalo 6. I-7.Ukukhanya okuzinzileyo kunye nokuqaqamba komhlaba kulungile, kulula ukupeyinta, ukufaka imibala, kunokutshizwa ngentsimbi, i-electroplating, i-welding kunye ne-bonding kunye nokunye ukusebenza kwasesekondari. 8. IABS inokwenziwa ibe yimibala eyahlukeneyo njengoko kufuneka njalo. Ukuba ukongeza ilangatye nekudodobalisa additive okanye anti-ultraviolet additive kwi ABS, inokusetyenziswa ukuvelisa amacandelo izixhobo ngaphandle okanye indawo ubushushu eliphezulu.

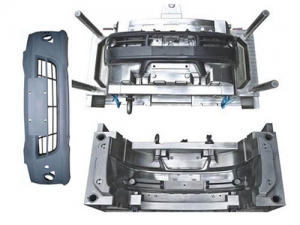

Ukusetyenziswa kweplastiki ye-ABS resinI-ABS ineenyawo zayo kuluhlu olubanzi lwezicelo ngenxa yokusebenza kwayo ebanzi kunye nenkqubo elungileyo yokusebenza. Imixholo ephambili yile ilandelayo: 1. I-Automobile Industry Iindawo ezininzi kushishino lweemoto zenziwe nge-ABS okanye i-ABS alloys. Umzekelo: idashboard yemoto, ipaneli yangaphandle yomzimba, ipaneli yokuhombisa ngaphakathi, isondo, ipaneli yokugquma isandi, isitshixo somnyango, ibhamper, umbhobho wokungenisa umoya kunye nezinye izinto ezininzi ze-ABS zisetyenziswa kakhulu ekuhombiseni ngaphakathi kwemoto, njengebhokisi yeglavu kunye nebhokisi yebhokisi zenziwe nge-ABS enganyangekiyo bubushushu, iminyango yeengcango ephezulu kunye nezantsi, imaski yetanki lamanzi eyenziwe nge-ABS, kunye nezinye iindawo ezininzi ezenziwe nge-ABS njengezinto ezingafunekiyo. Isixa samalungu e-ABS asetyenziswa emotweni malunga ne-10 kg. Phakathi kwezinye izithuthi, inani leenxalenye zeABS ezisetyenzisiweyo nalo liyamangalisa. Ezona ndawo ziphambili emotweni zenziwe nge-ABS, ezinje ngedashboard ene-PC / ABS njengamathambo, umphezulu wenziwe ngefilimu yePVC / ABS / BOVC. 2. Izixhobo ze-elektroniki kunye nezombane iABS kulula ukutofwa kwigobolondo kunye neendawo ezichanekileyo ezinemilo entsonkothileyo, ubungakanani obuzinzileyo nembonakalo entle. Ke ngoko, iABS isetyenziswa ngokubanzi kwizixhobo zasekhaya nakwizinto ezincinci, ezinje ngeeseti zeTV, urekhodo, iifriji, iifriji, oomatshini bokuhlamba, izixhobo zokucoca umoya, izicoci zokucoca, oomatshini befeksi ekhaya, iaudiyo kunye neVCD. I-ABS ikwasetyenziswa ngokubanzi kwizicoci zokucoca kwaye iinxalenye ezenziwe yiABS zikwasetyenziswa nakwizitya zasekhitshini. Iimveliso zenaliti ye-ABS ngaphezulu kwe-88% yazo zonke iimveliso zeplastiki zeefriji. 3.Izixhobo zeOfisi Ngenxa yokuba i-ABS ine-gloss ephezulu kunye nokubumba okulula, izixhobo zeofisi kunye noomatshini bafuna ukubonakala okuhle kunye nesiphatho esihle, njengecala lomnxeba, ityala lememori, ikhompyuter, umatshini wefeksi kunye nekopi, iindawo zeABS zisetyenziswa ngokubanzi. Isixhobo se-4.Industrial Ngenxa yokuba i-ABS inobumba obulungileyo, kuluncedo ukwenza izixhobo zekrisimesi kunye negobolondo ngobukhulu obukhulu, ukuguqulwa okuncinci kunye nobungakanani obuzinzileyo. Ezifana nokusebenza kwedeshibhodi, itafile yokusebenza, iphuli yolwelo, ibhokisi yamalungu, njl.

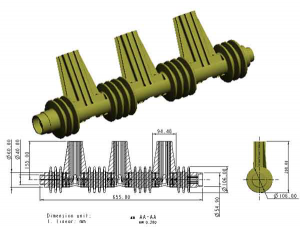

Uyilo lweemveliso kunye nokubumba

1. Ubungakanani bodonga lweemveliso: Ubungakanani bodonga lweemveliso bunxulumene nobude bokunyibilika kokunyibilika, ukusebenza kakuhle kwemveliso kunye neemfuno zokusetyenziswa. Umyinge wobude bokuhamba kwe-ABS inyibilike kubungakanani bodonga lwemveliso malunga ne-190: 1, eyahluka ngokwebakala. Ke ngoko, ubukhulu bodonga lweemveliso ze-ABS akufuneki bube mncinci kakhulu. Iimveliso ezifuna unyango lwe-electroplating, ubukhulu bodonga kufuneka bube buncinci ukunyusa ukunamathela phakathi kwento yokutyabeka kunye nomphezulu wemveliso. Ngesi sizathu, ubukhulu bendonga yemveliso kufuneka bukhethwe phakathi kwe-1.5 kunye ne-4.5 mm. Xa sijonga ubukhulu bodonga lweemveliso, kuya kufuneka siqwalasele ukufana kobungakanani bodonga, hayi umahluko omkhulu kakhulu. Kwiimveliso ekufuneka zenziwe ngombane, umphezulu kufuneka ucwecwe kwaye ungadibani, kuba la malungu kulula ukubambelela eluthulini ngenxa yempembelelo yombane, ekhokelela ekuqineni okungagungqiyo kwengubo. Ukongeza, ubukho beekona ezibukhali kufuneka kuthintelwe ukuthintela uxinzelelo loxinzelelo. Ke ngoko, kufanelekile ukufuna utshintsho lwe-arc kwii-engile eziguqukayo, kumalungu adibeneyo kunye namanye amalungu.

2. Ithambeka lokulimaza: Ithambeka elonakalisayo leemveliso linxulumene ngqo nokuncipha kwayo. Ngenxa yamabanga ahlukeneyo, iimilo ezahlukeneyo zeemveliso kunye neemeko ezahlukileyo zokwenza, i-shrinkage yokwakha ineyantlukwano, ngokubanzi kwi-0.3 0.6%, ngamanye amaxesha ukuya kuthi ga kwi-0.4 0.8%. Ke ngoko, ukuchaneka kobukhulu bokwenza iimveliso kuphezulu. Iimveliso ze-ABS, ithambeka lokudiliza lithathwa ngolu hlobo lulandelayo: icandelo eliphambili ziidigri ezingama-31 ecaleni kwendlela eyonakalisayo, kwaye indawo yenqanawa yi-1 degree 20'alongomhla wokonakaliswa. Kwiimveliso ezinemilo entsonkothileyo okanye ngoonobumba kunye neepateni, ithambeka lokudiliza kufuneka lenyuswe ngokufanelekileyo.

3. iimfuno zokukhutshwa: kuba ukugqitywa okubonakalayo kwemveliso kunempembelelo enkulu ekusebenzeni kokufakwa kombane, ukubonakala kwazo naziphi na iziva ezincinci kuya kubonakala emva kokufakwa kombane, ke ukongeza kwimfuno yokuba akukho mabala akhona kwindawo yokufa, Indawo esebenzayo yokukhutshwa kufuneka ibe nkulu, ungqamaniso lokusetyenziswa kweejector ezininzi kwinkqubo yokukhutshwa kufanelekile, kwaye amandla okukhutshwa kufuneka afane.

4. Ukukhupha umbane: Ukuthintela ukukhutshwa okungalunganga ngexesha lenkqubo yokuzalisa, tshisa i-melt kunye ne-seam lines, kufuneka uvule i-vent okanye i-vent slot enobunzulu obungaphantsi kwe-0.04 mm ukulungiselela ukukhutshwa kwegesi kwi Nyibilika intshi. 5. Imbaleki kunye nesango: Ukuze wenze i-ABS inyibilike igcwalise onke amalungu omngxuma ngokukhawuleza, ubukhulu bembaleki akufuneki bube ngaphantsi kwe-5 mm, ubukhulu besango kufuneka bube ngaphezulu kwe-30% yobukhulu yemveliso, kunye nobude besahlulo esithe nkqo (kubhekiswa kwinxalenye eya kungena kwisisu) kufuneka sibe malunga ne-1 mm. Indawo yokuma kwesango kufuneka igqitywe ngokwemfuneko yemveliso kunye nolwalathiso lokuhamba kwezinto. I-Ramp ayivumelekanga ukuba ibekho kumphezulu wokutyabeka weemveliso ekufuneka zenziwe ngombane.

Unyango oluphezulu kunye nokuhombisaI-ABS kulula ukuyipeyinta kunye nemibala. Inokutshizwa kwakhona ngesinyithi kunye neelectroplating. Ke ngoko, iinxalenye ze-ABS zihlala zihonjisiwe kwaye zikhuselwe ngukubumba ngenaliti kunye nokutshiza, ukushicilela isilika, ukutshiza i-electroplating kunye nokunyathela okushushu kumphezulu weenxalenye zokubumba. 1. I-ABS ineempawu ezilungileyo zenaliti, kwaye inokufumana amabakala ahlukeneyo okutya okuziinkozo, inkungu, umphezulu ogudileyo kunye nesipili ngomphefumlo. 2. I-ABS inobumbano obuhle bepeyinti, kwaye kulula ukufumana imiphezulu eyahlukeneyo ngombala ngokutshiza komphezulu. Kwaye ukuprintwa kwesikrini kweempawu ezahlukeneyo kunye neepateni. 3. I-ABS ineempawu ezifanelekileyo zokufaka i-electrochemical plating kwaye yiyo kuphela iiplastiki ezinokufumana indawo yentsimbi ngokufaka i-electroless plating. Iindlela zokufaka ngaphandle kombane zibandakanya ukutyabeka ngobhedu okungabunjwanga, ukungabinanto kwe-nickel, ukungabinanto ngombala wesilivere kunye nesingxobo se-chromium.