Die ekubunjweni ngumngundo

Inkcazo emfutshane:

Die ekubunjweni ekubunjweniluhlobo lwezixhobo zentsimbi eyahlulayo. Isikhunta sokufa siqulathe ukungunda "isigubungelo sokufa isiqingatha" kunye nesinye "isixhobo sokukhupha isiqingatha.

I-die-casting molds isetyenziselwa ukwenza iinxalenye zesinyithi ezingafakwanga kunye nesakhiwo esimbaxa kunye nemilo. Njengokuveliswa kobunzima bealuminium ingxubevange, zinc ingxubevange, ingxubevange wemagniziyam kunye nobhedu iinxalenye ingxubevange, ezisetyenziswa ubukhulu becala imoto, elektroniki, izixhobo zombane, ifenitshala, zonyango kunye nezinye iimveliso.

Yintoni die ekubunjweni ukungunda

Die eyahlulayo ligama elifutshane lokuphosa uxinzelelo. Yindlela yokugcwalisa umngxunya wokuphosa umngundo ngesinyithi esingamanzi okanye esisezantsi solusu phantsi koxinzelelo oluphezulu

ngesantya esiphezulu kwaye uqinise ngokukhawuleza ukufumana ukulahlwa. Isibumbeko esisetyenzisiweyo sibizwa ngokuba ngumngxuma wokufa.

Iindidi ekubunjweni die ekubunjweni

Ngokwentsebenzo, inokwahlulahlulwa ibe ngamacandelo ezakhiweyo kunye neendawo zokuhombisa.

Ngokwemeko yesicelo, inokwahlulahlulwa ibe ngumngundo weemoto, imveliso ye-3C ifa isikhunta, into yokudlala ifa ikhupha isikhunta, njl.

Ngokutsho iimpawu imilo kunye nodonga ubukhulu, oko kwakhona lungohlulwa lube ibhityile obhityileyo die-eyahlulayo ukungunda, ibhokisi die-eyahlulayo ukungunda kunye idiskhi die-eyahlulayo ukungunda

Ukufa umatshini wokuphosa, ukufa kwe-alloy kunye ne-die-casting die zizinto ezintathu zemveliso yokufa, enye yazo ibaluleke kakhulu.

Uhlobo umatshini die-eyahlulayo, die iparameters zesakhiwo, inkqubo die-eyahlulayo kunye noyilo mveliso zixhomekeke die-ekubunjweni izinto ingxubevange, ngoko ke ukuhlelwa die-eyahlulayo kufa ngokokuloba izinto ingxubevange kakhulu ifanelekileyo yokwenza imveliso. bona die-eyahlulayo ukungunda zinokwahlulwa aluminium ingxubevange die-eyahlulayo ukungunda, zinc ingxubevange die-eyahlulayo ukungunda, wemagniziyam ingxubevange die-eyahlulayo ukungunda kunye nobhedu ingxubevange die-eyahlulayo ukungunda. Iinkcukacha zezi zilandelayo:

1) .Aluminium ufe bephosa ukungunda

2) .Zinc ufe bephosa ukungunda

3) .Magnesium alloy die-casting mold

4) .Copper ingxubevange die-eyahlulayo ukungunda

5) .Sintering nokuvunda

IAluminiyam iyafa ekubunjweni komngundo

Zinc ufe bephosa ukungunda

Ukufa ekubunjweni komngundo

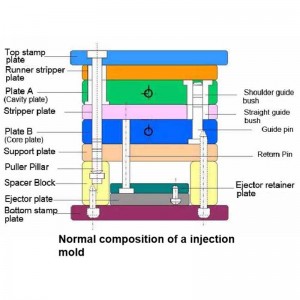

Ukwakhiwa kwesikhunta sokufa kunokuhlulwa kubini kubini:

Ukumiswa kwesiqingatha sokubumba:Ukuze ilungiswe kwipleyiti yokubumba esisigxina yomatshini wokuphosa ofayo, ngesitshixo esidityaniswe ngombhobho okanye kwigumbi loxinzelelo;

Isiqingatha sokubumba esihambisekayo:Ukuze ilungiswe ipleyiti obandayo kumatshini die-eyahlulayo, kwaye wafudukela nembasa ipleyiti ukuvula nokuvala ukungunda. Xa kuvalwa ukungunda, isikhunta sokubumbela kunye nenkqubo yokuphosa ziyenziwa, kwaye isinyithi esingamanzi sizalisa isikhunta phantsi koxinzelelo oluphezulu. Xa uvula ukungunda, isiqingatha sokubumbela esishenxiswayo kunye nokumisa okumileyo kuyahlulwa, kwaye ukulahlwa kuyatyhalwa ngaphandle ngoncedo lwendlela yokukhutshwa ebekwe kwisiqingatha sokubumbana.

Ubume bokufa bokuphonononga kubandakanya ezi nkqubo ziphantsi zilandelayo ngokwemisebenzi yazo:

1) Umngxunya: umphezulu we-sprue (umkhono we-sprue); Inkcitho: isango langaphakathi lomphezulu wangaphakathi.

2) Isikhokelo seendawo: isikhokelo seposi; umkhono umkhono.

3) Launch mechanism Push rod (thimble), reset reset, push push rod fixing plate, tyhala ipleyiti, tyhala ipleyiti isikhokelo iposti, tyhala ipleyiti isikhokelo umkhono.

4) Icala elisecaleni lokutsala indlela ye-Boss, umngxuma (kwicala), ibhloko yebheji, umda wentwasahlobo, isikrufu.

5) Inkqubo yokuphuphuma komkhumbi, umkhombe wokukhupha.

6) Ukuxhasa iindawo.

Indawo yokumisa ipleyiti yesiseko sokubumbela, ipleyiti yesiseko sokubumbela, ibhloko yabasebenzi (ukuhlangana, ukubeka indawo, umsebenzi wokufaka).

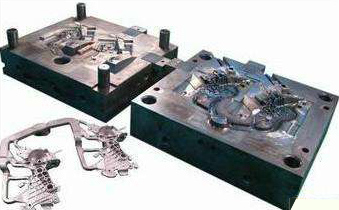

Umahluko phakathi die ekubunjweni ngumngundo kunye nokuvunda zeplastiki:

1.Uxinzelelo lwenaliti yokufa kokufa kukhulu. Ke ngoko, itemplate kufuneka ibengqindilili. Thintela deformation.

2. Isango lokufa ekubunjweni komngundo lahlukile kuleyo yokubumba ngenaliti. Uxinzelelo oluphezulu lokuqukuqela kwezinto kuya kubola ngokwezixhobo zokuqhekeka.

3. Undoqo die ekhupha kufa akufuneki ukuba lukhuni. Ngenxa yokuba iqondo lobushushu kwindawo yokufa ingaphezulu kwe-700 ℃. Ke ngoko, ukubumba ngakunye kulingana nokucima. Umqala uya kuba nzima ngakumbi. Ukubumba kwenaliti ngokubanzi kufuneka kucinywe ngaphezulu kwe-hrc52.

4. Ngokubanzi, kwisisu sokufa-ukulahla ukufa kufuna unyango lwe-nitriding. Thintela ingxubevange ekuncamatheleni kumngxunya wokubumba.

5. Ngokubanzi, umhlwa die bephosa kufa lukhulu kakhulu. Umphezulu wangaphandle ngokubanzi ubuhlaza.

6. Xa kuthelekiswa nokubumba ngenaliti. Ukucinywa okufanelekileyo kwenxalenye ehambisekayo yesixhobo sokufa (njengesixhobo sokutsala esingaphakathi) kufuneka sibe sikhulu. Ngenxa yokuba iqondo lobushushu eliphezulu lenkqubo yokuphosa ukufa iya kubangela ukwanda kwe-thermal. Ukuba kugqitywe incinci kakhulu, ukungunda kuya kubambeka.

7. Umphezulu wokuvalelisa ukufa-ukulahla kufa kuneemfuno ezifanayo. Kuba ukufuma kwengxubevange kungcono kakhulu kunaleyo yeplastiki, kuyingozi kakhulu kubushushu obuphezulu kunye nokuhamba koxinzelelo oluphezulu lokubhabha ngaphandle kwendawo yokuzahlula.

8. Inaliti yokubumba ihlala ixhomekeke kwi-thimble. Umphezulu wokwahlula unokungena. Ukubumba die-eyahlulayo kufuneka kubonelelwe slot zeemoto kunye nebhegi ukuqokelela ingxowa (ukuqokelela intloko izinto ebandayo).

9. Ukuyila akuhambelani. Isantya Inaliti die ekubunjweni die ngokukhawuleza. Inqanaba lokuqala loxinzelelo lwenaliti. Umngundo weplastikhi uhlala wahlulwe ngenaliti, uxinzelelo.

10.Umbumbulu wokuphosa izinto ezimbini zokubumba (andikaboni zimbumba zintathu zokuphosa ngoku). Izakhiwo ezahlukeneyo zeemveliso zeplastiki zokubumba zihlukile. 3 ngumngundo ipleyiti zixhaphakile. Inani kunye nokulandelelana kokuvula kuyahambelana kunye nesakhiwo sokufa. I-thimble yesikwere ayiqhelekanga isetyenziswa ekubunjweni komngundo. Isilinda.

11. I-pin ethambekileyo (ubushushu obuphezulu kunye nesisombululo esifanelekileyo sesisombululo) kulula ukuba ijamu, ekhokelela kwimveliso yokubumba engazinzanga. Ukongeza, ukungunda kweplastikhi kunye nokufa komngundo kwenziwa ngentsimbi eyahlukileyo; zeplastiki ngumngundo ngokubanzi isebenzisa 45 × intsimbi, T8, T10 kunye nezinye intsimbi, lo gama die-eyahlulayo

Inkampani kaMestech igxile kwicandelo lokuvelisa ukungunda ngokuchanekileyo kunye nezahlulo zemveliso ngaphezulu kweminyaka eyi-10, ngobuchwephesha beshishini obuphambili kunye namava atyebileyo okuvelisa ukungunda. Iimveliso zenkampani ikakhulu iimveliso zeplastiki okanye izinto zeqokobhe ezinje ngemveliso yedijithali ye-elektroniki, izixhobo zonyango, iimveliso zeentsana, njl.njl. Kananjalo neemveliso zeplastikhi ezinje ngeemveliso zasekhaya kunye nezinto ezizenzekelayo. Inkampani inesakhono esomeleleyo sokuyilwa kwesakhiwo kunye nokuyilwa kwesikhunta, esinokubonelela abathengi ngezindululo ezenziwe ngakumbi kubume bemveliso kunye nezicwangciso ezifanelekileyo zokubumba