Uyila njani iinxalenye zeplastiki

Inkcazo emfutshane:

Ukuya uyilo iinxalenye zeplastikiKukuchaza ubume, ubungakanani kunye nokuchaneka kwamalungu, ngokusekwe kwindima edlalwa ngamalungu kwimveliso, kunye nomgaqo wenkqubo yokubumba yeplastiki. Iziphumo zokugqibela yimizobo yokuvelisa ukungunda kunye nenxalenye yeplastiki.

Ukuveliswa kwemveliso kuqala kuyilo. Ukuyilwa kwamalungu eplastiki ngokuthe ngqo kugqiba ukufezekiswa kwesakhiwo sangaphakathi, indleko kunye nokusebenza kwemveliso, kunye nokumisela inyathelo elilandelayo lemveliso yokubumba, indleko kunye nomjikelo, kunye nenkqubo yokubumba yenaliti kunye nenkqubo yokulungisa emva kunye neendleko.

Iindawo zeplastiki ezisetyenziswa ngokubanzi kwiimveliso ezahlukeneyo, izibonelelo kunye nobomi babantu kuluntu lwanamhlanje. Iindawo zeplastiki zifuna iimilo ezahlukeneyo kunye nemisebenzi. Basebenzisa izinto zeplastiki kwaye iipropathi zabo ziyahluka. Kwangelo xesha, zininzi iindlela zokwenza izinto zeplastiki kwishishini. Ke ukuyila iinxalenye zeplastiki ayingomsebenzi olula.

Icandelo eliyilo loyilo kunye nezinto ezibonakalayo ziveliswa ngeendlela ezahlukeneyo. Ukulungiswa kweplastiki yokubumba ikakhulu kubandakanya apha ngezantsi:

1.inaliti yokubumba

2.blowing yokubumba

3.compression yokubumba

4.ukubumba iintambo

5. ukuqulunqa izinto

6.ukuxhonywa

7. ukubumba

8.ukutsha

Zininzi iindlela zokwenza imveliso ngobuninzi. Inaliti yokubumba yindlela ethandwayo yokuvelisa, kuba inaliti ukubumba 50% ~ 60% iinxalenye zeplastiki ziveliswa byb ziphene yokubumba, yinto-high speed amandla yemveliso.

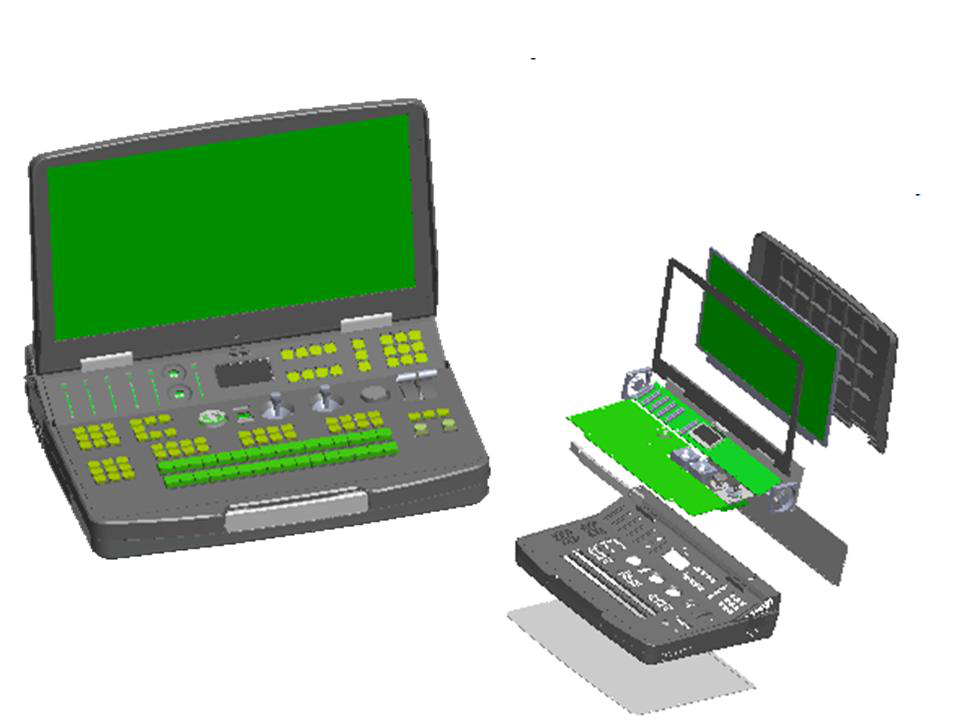

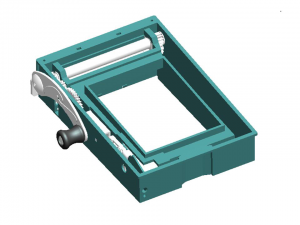

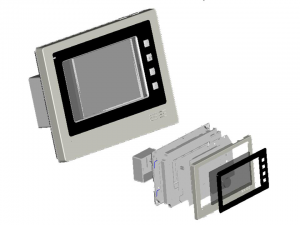

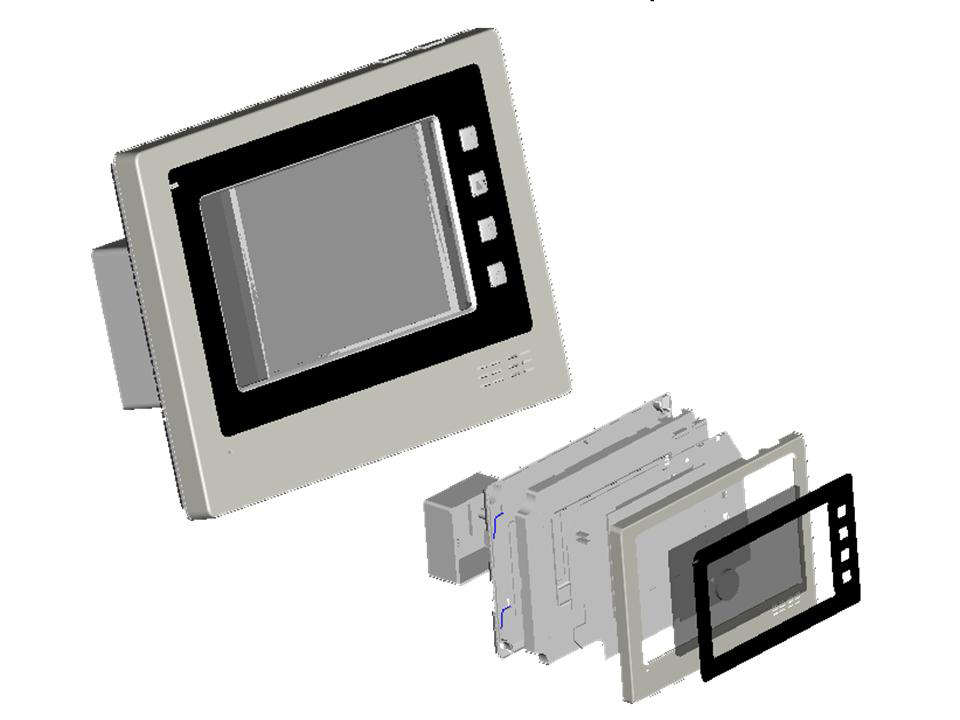

Bonisa ityala lezinto ezithile zeplastiki eziyilwe:

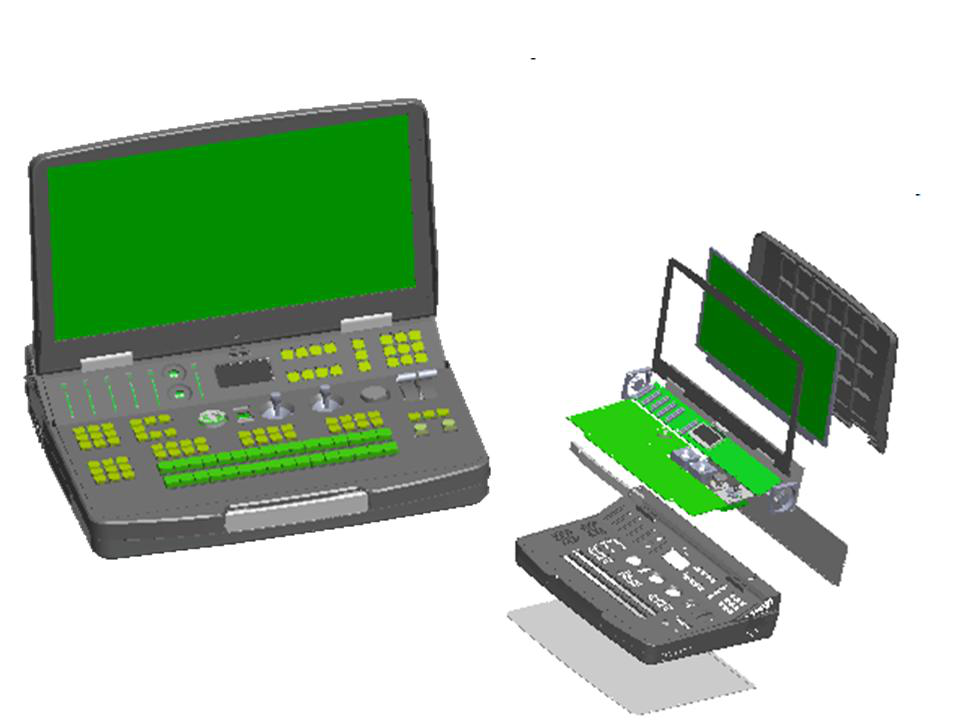

Ukuvalelwa kweplastiki yefowuni yombono

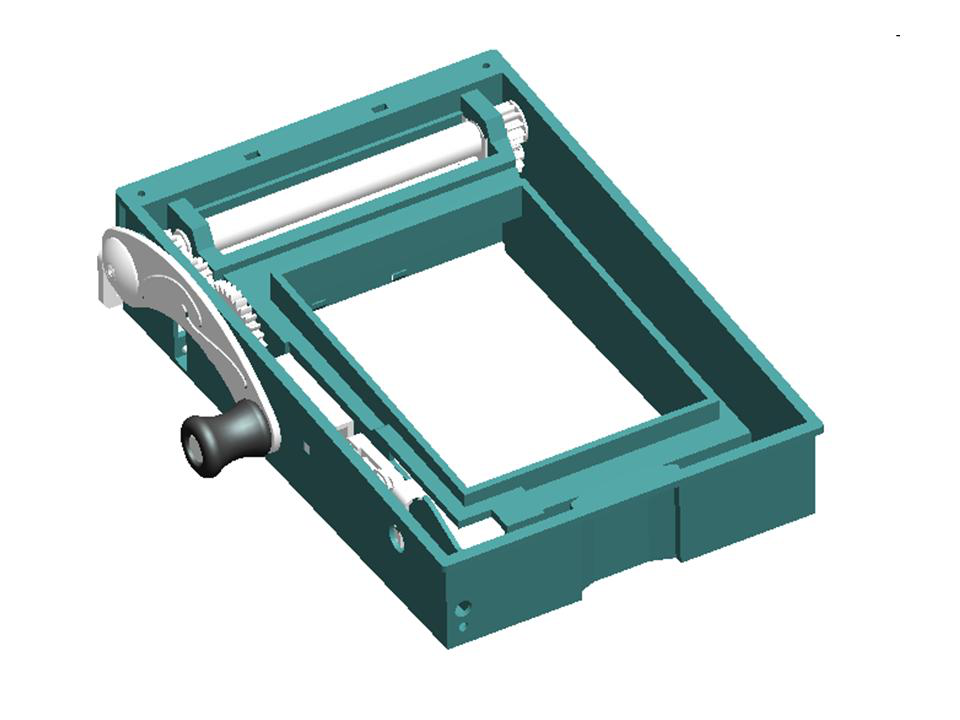

Iindawo zeplastiki koomatshini

Iimeko zeplastiki ze-elektroniki

Indlu yeplastiki yesixhobo

Apha ngezantsi sabelana ngeenkcukacha ngendlela yokuyila iinxalenye zeplastiki kwimiba emithathu

* Iingcebiso ezili-10 zokuyilwa kweeplastiki kufuneka uyazi

1.Qikelela uyilo lokuvela kunye nobungakanani bemveliso.

Eli linyathelo lokuqala kuyo yonke inkqubo yoyilo. Ngokophando lwentengiso kunye neemfuno zabathengi, misela ukuvela nokusebenza kweemveliso, kunye nokwenza imisebenzi yophuhliso lwemveliso.

Ngokomsebenzi wophuhliso, iqela lophuhliso liqhuba uhlalutyo lobuchule kunye nobuchwephesha kwimveliso, kunye nokwakha imodeli yokubonakala kwemveliso ye-3D. Emva koko, ngokwenzeka komsebenzi kunye nendibano yemveliso, iindawo ezinokubakho zicwangcisiwe.

2.Sahlula iinxalenye ezithile kwimizobo yemveliso, khetha uhlobo lwentlaka yeplastiki yeplastiki

Eli nyathelo lokwahlula iinxalenye kwimodeli ye-3D efunyenwe kwinyathelo elidlulileyo kwaye uyile ngokwabantu ngabanye. Ngokweemfuno zokusebenza kwamalungu, khetha izinto zeplastiki ezifanelekileyo okanye izixhobo zekhompyutha. Umzekelo, i-ABS ihlala isetyenziswa kwi

iqokobhe, i-ABS / BC okanye i-PC iyacelwa ukuba ibe neepropathi ezithile zoomatshini, iinxalenye eziselubala ezifana nesibane, isithuba sesibane se-PMMA okanye iPC, izixhobo okanye ukunxiba iinxalenye zePOM okanye iNylon.

Emva kokukhetha umbandela wamalungu, uyilo lweenkcukacha lunokuqaliswa.

3.Chaza ii-angles eziyilwayo

Uyilo lweeengile zivumela ukususwa kweplastikhi ekubunjweni. Ngaphandle kwee-angles eziyilwayo, icandelo liya kubonelela ngokuchasana okubonakalayo ngenxa yokuxabana ngexesha lokususwa. Uyilo lwee-angles kufuneka lubekhona ngaphakathi nangaphandle kwesahlulo. Ubunzulu benxalenye, kokukhona kufuneka i-engile yoyilo. Umgaqo olula wesithupha kufuneka ube nedigri ye-1 yoyilo ye-engile nge-intshi. Ukungabinayo i-engile yoyilo eyoneleyo kunokubangela ukukrwada kumacala enxalenye kunye / okanye amanqaku amakhulu ejector pin (ngakumbi koku kamva).

Uyilo lwee-angles zangaphandle kwangaphandle: Ubunzulu benxalenye, enkulu i-engile yoyilo. Umgaqo olula wesithupha kufuneka ube nedigri ye-1 yoyilo ye-engile nge-intshi. Ukungabinayo i-engile yoyilo eyoneleyo kunokubangela ukukrwada kumacala enxalenye kunye / okanye amanqaku amakhulu ejector pin (ngakumbi koku kamva).

Ngokwesiqhelo, ukuze ujongeke umphezulu, ubume benziwe kumacandelo. Udonga olunombala lurhabaxa, ukungqubana kukhulu, kwaye akukho lula ukuwususa kwisisu, ngenxa yoko kufuna i-engile enkulu yokuzoba. Ubume oburhabaxa yile, i-engile enkulu yoyilo efunekayo.

4.Chaza ubukhulu bodonga / ubukhulu obufanayo

Ubumba obungqongqo abufuneki ekubumbeni ngenaliti ngenxa yezi zizathu zilandelayo:

I-1) .Ixesha lokupholisa lihambelana isikwere sobukhulu bodonga. Ixesha lokupholisa ixesha elide lokuqina liya kuloyisa uqoqosho lwemveliso ngobuninzi. (umqhubi ombi wobushushu)

2) .Icandelo leThicker liyancipha ngaphezulu kwecandelo elincinci, ngaloo ndlela lazise ukuncipha okwahlukileyo okukhokelela kwimfazwe okanye kumatshini wokuntywila njl.njl. (Ukuncipha kweempawu zeplastikhi kunye neempawu ze-pvT)

Ke ngoko sinomgaqo osisiseko kuyilo lwenxalenye yeplastiki; kangangoko kunokwenzeka ubukhulu bodonga kufanele ukuba bube ngokufanayo okanye buhlale buphuma kwinxalenye. Ubungakanani bodonga bubizwa ngokuba ubukhulu bodonga.

Ukuba kukho naliphi na icandelo eliqinileyo kule nxalenye, kufuneka yenziwe ingenanto ngokuzisa undoqo. Oku kuya kuqinisekisa ubukhulu bodonga obufanayo obujikeleze umxholo.

3) Zithini iingqwalaselo zokuthatha isigqibo sodonga lobukhulu?

Kufuneka ibengqindilili kwaye iqine ngokwaneleyo ukulungiselela umsebenzi. Ubungakanani bodonga bunokuba yi-0.5 ukuya kwi-5mm.

Kuya kufuneka icekeceke ngokwaneleyo ukuze ipholile ngokukhawuleza, ikhokelele kubunzima bomgangatho ophantsi kunye nemveliso ephezulu.

Nawuphi na umahluko kubukhulu bodonga kufuneka ugcinwe ubuncinci kangangoko kunokwenzeka.

Icandelo leplastiki elinobungakanani obahlukeneyo bodonga liya kuba namava okupholisa ngokwahlukileyo kunye nokuncipha okungafaniyo. Kwimeko enjalo ukufikelela kunyamezelo olusondeleyo kuba nzima kakhulu kwaye amaxesha amaninzi akunakwenzeka. Apho umahluko wobukhulu bodonga kubalulekile, inguqu phakathi kwezi zimbini kufuneka ithi chu.

Uyilo lwe-5.Ukudibanisa phakathi kwezahlulo

Ngokwesiqhelo kufuneka sidibanise amaqokobhe amabini kunye. Ukwenza igumbi elivalelweyo phakathi kwabo ukubeka izinto zangaphakathi (indibano ye-PCB okanye indlela).

Iindidi eziqhelekileyo zonxibelelwano:

1). Amagwegwe Snap:

Ukunxibelelana kwamagwegwe okuxhaphakileyo kusetyenziswa rhoqo kwiimveliso ezincinci neziphakathi. Uphawu lwayo kukuba ii-snap hooks zihlala zibekwa emaphethelweni eendawo, kwaye ubungakanani bemveliso bunokwenziwa buncinci. Xa ihlanganisiwe, ivaliwe ngokuthe ngqo ngaphandle kokusebenzisa naziphi na izixhobo ezinje nge-screwdriver, i-welding ye-ultrasonic kunye nezinye. Ukungancedi kukuba ii-snap hooks zinokubangela ukuba ukungunda kube nzima ngakumbi. Isixhobo esityibilikisayo kunye neendlela zokuphakamisa ziyafuneka ukuze kuqondwe uqhagamshelo lwe-snap hooks kunye nokunyusa iindleko zokubumba.

2). Amalungu okujija:

Amalungu okujija aqinile kwaye athembekile. Ngokukodwa, i-screw + nut fixation inokwethenjelwa kwaye ihlala ixesha elide, ivumela ukungabikho kwezinto ezininzi ngaphandle kokuqhekeka. Ukuqhagamshela kwesikrini kulungele iimveliso ezinamandla amakhulu okutshixa kunye nokudiliza okuninzi. Ukungancedi kukuba ikholamu yokujija ithatha indawo engaphezulu.

3). Abaphathi bokunyuka:

Ukunxibelelana kwabaphathi kukulungisa iinxalenye ezimbini ngokulungelelaniswa okuqinileyo phakathi kwabaphathi kunye nemingxunya. Le ndlela yoqhagamshelo ayinamandla ngokwaneleyo ukuvumela ukudityaniswa kwemveliso. Ingxaki kukuba amandla okuvala aya kuncipha njengoko ixesha lokuqhaqhafaza landa.

4). Ukudibanisa i-Ultrasonic:

Ultrasonic welding kukubeka la macandelo mabini kwisikhunta se-ultrasonic kunye nokufakela umphezulu womnxeba phantsi kwentshukumo yomatshini we-welding ye-ultrasonic. Ubungakanani bemveliso bunokuba buncinci, ukubumba kwenaliti kulula, kwaye uqhagamshelo luqinile. Ukungancedi kukusetyenziswa kwe-ultrasonic mold kunye ne-ultrasonic welding machine, ubungakanani bemveliso abukwazi ukuba bukhulu kakhulu. Emva kokuqhaqha, iinxalenye ze-ultrasonic azinakusetyenziswa kwakhona.

6.Ukucuthwa

Ngaphantsi kwezinto ziphazamisa ukususwa kwesiqingatha sokubumba. Izicucu zinokubonakala naphi na kuyilo. Ezi azamkelekanga, ukuba zimbi kakhulu kunokuswela i-engile yoyilo kwinxalenye. Nangona kunjalo, ezinye iincutshulwa ziyimfuneko kwaye / okanye azinakuphepheka. Kwezo meko, kuyimfuneko

undercuts ziveliswa ngokushenxisa / ukuhambisa iinxalenye ekubumbeni.

Gcina ukhumbula ukuba ukwenza i-undercuts kuyabiza ngakumbi xa uvelisa ukungunda kwaye kufuneka kugcinwe ubuncinci.

7.Iimbambo zokuxhasa / iiGussets

Iimbambo kwinxalenye yeplastiki ziphucula ukuqina (ubudlelwane phakathi komthwalo kunye nenxalenye yokuphambuka) kwenxalenye kunye nokwandisa ukuqina. Ikwaphucula ukubola njengoko bekhawulezisa ukunyibilika kokuya kwicala lobambo.

Iimbambo zibekwe ecaleni kolona xinzelelo luphezulu kunye nokuphambuka kwiindawo ezingabonakaliyo zesahlulo. Ukuzaliswa komngundo, ukuncipha kunye nokukhutshwa kufuneka kuchaphazele nezigqibo zokubeka ubambo.

Iimbambo ezingadibani nodonga oluthe nkqo akufuneki ziphele ngesiquphe. Ukutshintsha ngokuthe ngcembe eludongeni ngegama kufuneka kunciphise umngcipheko woxinzelelo lwexinzelelo.

Ubambo - ubukhulu

Iimbambo kufuneka zibe nemilinganiselo elandelayo.

Ubunzima bembambo kufuneka bube phakathi kwe-0.5 ukuya kwi-0.6 yamaxesha ngegama lokuqina kodonga ukuthintela uphawu lokuntywila.

Ukuphakama kwembambo kufuneka kube zii-2,5 ukuya kwezi-3 amaxesha obukhulu bodonga.

I-Rib kufuneka ibe ne-0.5 ukuya kwi-1.5-degree degree draft angle ukuze iququzelele ukukhutshwa.

Isiseko sebambo kufuneka sibe ne-radius 0.25 ukuya kwi-0.4 amaxesha ngokobukhulu bodonga lobukhulu.

Umgama phakathi kweembambo ezimbini kufuneka ube ngamaxesha ama-2 ukuya kwayi-3 (okanye nangaphezulu) ubukhulu bodonga.

Imiphetho ehlaziyiweyo

Xa iindawo ezimbini zidibana, zenza ikona. Kwikona, ubukhulu bodonga bonyuka ukuya kumaxesha angama-1.4 ubukhulu bodonga. Oku kubangela ukuncipha umahluko kunye noxinzelelo olubunjiweyo kunye nexesha elide lokupholisa. Ke ngoko, umngcipheko wokusilela kwinkonzo uyanda kwiikona ezibukhali.

Ukusombulula le ngxaki, iikona kufuneka zilungiswe ngeradiyo. Radius kufuneka ibonelelwe ngaphandle nangaphakathi. Ungaze ube nembombo ebukhali yangaphakathi njengoko ikhuthaza ukuqhekeka. I-Radius kufuneka ibe njalo ukuze iqinisekise kumgaqo wobukhulu bodonga rhoqo. Kukhethwa ukuba nobubanzi be-0.6 ukuya kwi-0.75 yamaxesha odonga lobungakanani kwiikona. Ungaze ube nembombo ebukhali yangaphakathi njengoko ikhuthaza ukuqhekeka.

Uyilo lomphathi we9

Sisoloko sisebenzisa izikrufu ukulungisa amatyala amabini esiqingatha kunye, okanye ukubopha iPCBA okanye ezinye izinto kumalungu eplastiki. Ke abaphathi bokujija sisakhiwo sokujija ngaphakathi kunye neendawo ezizinzileyo.

Umphathi we-screw u-cylindrical in shape. Umphathi unokudibaniswa kwisiseko kunye nenxalenye yomama okanye inokudibaniswa ecaleni. Ukuqhagamshela ecaleni kunokubangela icandelo leplastiki elingathandekiyo, elinganqwenelekiyo njengoko kunokubangela uphawu lokuntywila kunye nokunyusa ixesha lokupholisa. Le ngxaki ingasombululwa ngokuqhagamshela umphathi ngakwimbambo ukuya eludongeni lwecala njengoko kubonisiwe kumzobo. Umphathi unokwenziwa aqine ngokubonelela ngeembambo ze-buttress.

Isikere sisetyenziselwa umphathi ukukhawulezisa enye indawo. Kukho uhlobo lokwenza imisonto kunye nohlobo lokunyathela kwezikrufu. Izikulufu zokwenza umsonto zisetyenziswa kwi-thermoplastics kunye nezikrufu zokusika imisonto zisetyenziselwa iinxalenye zeplastiki ze-thermoset ze-inelastic.

Umsonto owenza izikrufu uvelisa imisonto yabasetyhini eludongeni lwangaphakathi lomphathi ngokuhamba kubanda- iplastikhi ikhubazekile ekuhlaleni kunokuba isikwe.

Isikrini umphathi kufuneka ubungakanani obufanelekileyo bokumelana nemikhosi yokufaka isikrufu kunye nomthwalo obekwe kwisikrufu kwinkonzo.

Ubungakanani besizalo sokuzala kwisikrufu kubalulekile ekumelaneni nomtya wokuhluba kunye nokujija ukukhupha.

Ububanzi obungaphandle bebhosi kufuneka bube bukhulu ngokwaneleyo ukuba bumelane noxinzelelo lwehupula olubangelwa ngumsonto.

Ukuzalela kunedayamitha encinci xa kungenwa ikhefu ubude obufutshane. Oku kunceda ekufumaneni isikrufu ngaphambi kokuqhuba. Kukwanciphisa uxinzelelo kwindawo evulekileyo yomphathi.

Abavelisi bePolymer banika izikhokelo zokumisela ubungakanani bomphathi wezixhobo zabo. Abavelisi besi sikisi bakwanika nezikhokelo zobungakanani besitayile esifanelekileyo.

Unonophelo kufuneka lwenziwe ukuze kuqinisekiswe amalungu omeleleyo e-weld ajikeleze i-screw bore in boss.

Unonophelo kufuneka lwenziwe ukuthintela uxinzelelo olubunjiweyo kubaphathi njengoko lunokungaphumeleli phantsi kobundlobongela.

Ukuzalela kumphathi kufuneka kube nzulu kunobunzulu bomsonto.

Umhlobiso we-10

Ngamanye amaxesha, ukuze sikhangeleke kakuhle, sihlala sinyanga ngokukodwa kumphezulu weplastiki.

Ezifana nokuthungwa, ukuqaqamba okuphezulu, ukupeyinta ukutshiza, ukukrola kwe-laser, ukunyathela okushushu, i-electroplating njalo njalo. Kuyimfuneko ukuba ithathele ingqalelo kuyilo lwemveliso kwangaphambili, ukunqanda ukuqhubekeka okulandelayo akunakufezekiswa okanye utshintsho lobungakanani oluchaphazela indibano yemveliso.