Ukuhonjiswa kwe-In-Mold-IML

Inkcazo emfutshane:

Ukuhonjiswa kwe-In-Mold (siyibize ngokuba yi-IMD) yitekhnoloji eyaziwayo yokuhombisa umhlaba kwihlabathi. Isetyenziselwa ukuhombisa umphezulu kunye nokusebenza kwepaneli yezixhobo zombane zasekhaya. Ihlala isetyenziswa kwiphaneli kunye nomqondiso welensi yefowuni yefowuni kunye negobolondo, ipaneli yokulawula umatshini wokuhlamba, iphaneli yokulawula ifriji, iphaneli yokulawula imeko yomoya, ideshibhodi yemoto, iphaneli yokulawula irayisi kunye nokunye.

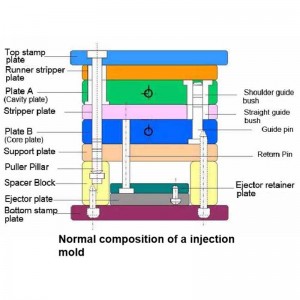

I-IMD yahlulwe yayi-IML (i-IMF ye-IML) kunye ne-IMR, umahluko omkhulu phakathi kwezi nkqubo zimbini kukuba ingaba umphezulu wemveliso unefilimu yokhuselo ebonakalayo.

I-IMD ibandakanya i-IML, IMF, IMR

I-IML: KU-MELLING LABEL (izinto zokuprinta kunye neeplastiki)

I-IMF: KU-MOLDING FILM (efanayo ne-IML)

I-IMR: UFUNDILE

I-IML (KWI-LABEL LABEL): Inkqubo ephawuleka kakhulu ye-IML yile: umphezulu lomaleko wefilimu eqaqambileyo eqinileyo, embindini ngumaleko wokuprinta, umva lomaleko lweplastiki, kuba i-inki ibambe phakathi, ingaba ukuthintela umphezulu ekukrwemeni kunye neabrasion, kwaye unokugcina umbala oqaqambileyo kwaye ungacimi ixesha elide. Ezi mpawu zenza iimveliso ze-IML zisetyenziswe ngokubanzi.

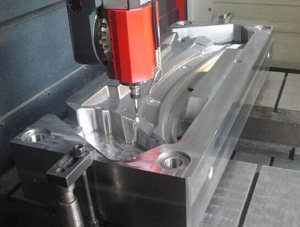

Inkqubo ye-IML: ukusika kwefilimu ye-PET- ukuprinta kweenqwelomoya-ukomisa i-inki-ukunamathela kwifilimu yokukhusela-ukubetha umngxunya -Ukubumba izinto -ukucheba ubume bepheripherali-ukubumba ngenaliti.

Ubume benqanaba ezintathu bemveliso ye-IML:

1. Umphezulu: Ifilimu (ifilimu ye-PET, ukuprinta nayiphi na ipateni kunye nombala). Iinkuni, i-cortex, u-bamboo, ilaphu, inkohliso, isikhumba sokulinganisa, ilaphu lokulinganisa, isinyithi sokulinganisa kunye njalo njalo;

2, umaleko ophakathi: i-inki (i-Ink), iglu, njl.

3, ezantsi: iplastiki (ABS / PC / TPU / PP / PVC, njl).

I-IMR (KWI-ROLLER EBANDLILEYO): Kule nkqubo, ipateni iyashicilelwa kwifilimu, kwaye ifilimu kunye nomngundo wobumbano zibotshelelwe ngumxhasi wefilimu yokubumba inaliti.

Emva kwenaliti, umaleko we-inki onepateni wohlulwe kwifilimu, kwaye umaleko we-inki ushiywe kwinxalenye yeplastiki ukufumana indawo yeplastiki enepateni yokuhombisa.

Akukho bhanyabhanya ukhuselo ubonakalayo kwimveliso yokugqibela, kwaye ifilimu iveliswa kuphela. Umntu ophetheyo kwinkqubo. Kodwa inzuzo ye-IMR ilele kwinqanaba eliphezulu lokuzenzekelayo kwimveliso kunye nexabiso eliphantsi lemveliso ngobuninzi. Iingxaki ze-IMR: Uluhlu oluprintiweyo lomgangatho kumphezulu wemveliso, ubukhulu bee-microns ezimbalwa, imveliso iya kuba lula ukunxiba umaleko wepateni oprintiweyo emva kwexesha, kodwa kube lula nokuphelelwa, nto leyo ekhokelela ekubeni ingabukeki umphezulu. Ukongeza, umjikelo wophuhliso lwemveliso mde, iindleko zophuhliso ziphezulu, umbala wepateni awunakufezekisa utshintsho oluncinci lwe-batch nayo inkqubo ye-IMR ayinakuboyisa ubuthathaka Kuyimfuneko ukucacisa kumxholo: Iingcebiso eziphambili ze-IMR ngumaleko wokukhululwa.

Inkqubo ye-IMR: Ifilimu yePET-iarhente yokukhutshwa-inki yokuprinta-Ukuprintwa kweBinder-inaliti yangaphakathi yeplastikhi-inki kunye neplastiki emva-kokuvula ukungunda, umboniso bhanyabhanya uza kukhulula ngokuzenzekelayo kwi-inki. Ngaphandle komgangatho wamashiti aprintiweyo, uthuli lunefuthe elikhulu kumgangatho wabo, kwaye imveliso yabo kufuneka yenziwe kwindawo ecocekileyo engenalo uthuli

Umahluko osisiseko phakathi kwe-IML kunye ne-IMR kukuba kukho imiphezulu eyahlukeneyo yeelensi, kunye nePET okanye ii-PC sheet kumgangatho we-IML kunye ne-inki kuphela kumphezulu we-IMR. Ukuxhathisa kwe-IML, ukunganyangeki kunye neepatheni zombala ixesha elide. I-IMR ilungele ukuveliswa kobunzima kunye nexabiso eliphantsi. I-IMR ayinxibanga kakhulu, iifowuni zeNokia neMoto ziyinxalenye yetekhnoloji ye-IMR, ixesha elithe kratya kancinci liya kubangela ukukrwela. Eyona nto iphambili kwi-IML kukuba ayinakuphunyezwa kuyo yonke itekhnoloji ye-IML, inikwe umda kuphela kwindawo eqhubekayo.

Iimpawu zeemveliso ze-IMD / ze-IML:

I-1, uyilo lwemveliso kunye nokucaca kombala, ayisoze yaphela, kunye nengqondo-ntathu;

2, imveliso inobomi inkonzo ende, umphezulu banxibe ukumelana kunye ukumelana ekuqaleni, kwaye igcina inkangeleko icocekile kwaye fresh.

3, ukuprinta ngokuchanekileyo + 0.05mm, kunokuprinta iipateni ezintsonkothileyo kunye nemibala;

I-4, iphethini kunye nombala unokutshintshwa nangaliphi na ixesha ngexesha lokuvelisa ngaphandle kokutshintsha ukungunda.

5. Ubume beemveliso ze-IML ayisiyiyo imilo yenqwelomoya kuphela, kodwa ikwayimbonakalo yomphezulu ogobileyo, umphezulu ogobileyo, umphezulu othambekileyo kunye nezinye izinto ezinembonakalo ekhethekileyo.

6, imveliso ayiqulathanga nasiphi na isincamathelisi esisekwe kwisinyibilikisi, esihlangabezana neemfuno zokusingqongileyo.

7. Ukuhanjiswa kweefestile kuphezulu njenge-92%.

8. Amaqhosha asebenzayo anamaqamza afanayo nesiphatho esihle. Amaqhosha adityaniswa xa efakwe kumbumba. Ubomi bezitshixo bunokufikelela ngaphezulu kwesigidi esinye samaxesha.

Ityala leplastikhi ye-IMD

Iphaneli engenanto ene-IML

Ityala le-IML ngesixhobo sonxibelelwano

Iphaneli ephambili yesixhobo se-IMD sasekhaya

Isicelo se-IML

Okwangoku, i-IML isetyenziswa ngokubanzi kwiinkalo ezininzi, ezinje ngeefestile, iigobolondo, iilensi, iphaneli yokulawula izixhobo zombane kunye nezinto zokuhombisa, eziza kuphuhliswa zibe ziilebheli zokulwa nomgunyathi kunye nomzi mveliso weemoto kwixa elizayo. Imveliso inentsebenzo elungileyo ye-sunscreen, inokusetyenziselwa iimpawu zemoto, ubunzima ukuya kuthi ga kwi-2H ~ 3H, inokusetyenziselwa iilensi zefowuni eziphathwayo, njl., Ubomi beqhosha bunokufikelela kumaxesha angaphezu kwesigidi esinye, inokusetyenziselwa abapheki belayisi kwaye ke ivuliwe.

I-IMD / IML inokuvelisa inxenye ngenkangeleko entle kwaye inxibe umphezulu onganyangekiyo. Kodwa ixabiso liphezulu kunendawo zomphezulu ngokubanzi. Ukuba imveliso yakho ifuna imveliso enjalo, nceda unxibelelane nathi.