Iindawo ngomshini

Inkcazo emfutshane:

Iindawo ngomshinizenza izinto ezisisiseko zezixhobo ezahlukeneyo zoomatshini nezixhobo. Izixhobo kunye nenkqubo esetyenziswa yiyo ukudibanisa elona nqanaba liphezulu loyilo lomatshini wangoku, izixhobo, ukunyibilikisa, oomatshini, izixhobo zombane, ulawulo lweshishini kunye nezinye iinkalo.

Ngokuphuhliswa kwetekhnoloji, iinxalenye ezichanekileyo kunye noomatshini badlala indima ebalulekileyo kwimveliso yezamashishini yanamhlanje. IMESTECH ibibonelela abathengi ngokuqhubekeka ngokuchanekileyo kwezinto zentsimbi kunye nezingezizo zesinyithi iminyaka.

Iyintoni indima yamacandelo esinyithi achanekileyo adlala kumzi mveliso wale mihla?

Isixhobo somatshini sisixhobo se "Umatshini woomama” . Phantse zonke izixhobo ezenziwa ngoomatshini azinakwahlukaniswa nokusetyenzwa ngoomatshini. Ngophuculo oluqhubekayo lobuchwephesha kunye nezixhobo, kukho imfuno enkulu yamacandelo okuchaneka, afana nokuhamba ngenqwelomoya, i-aerospace, imoto, ezonyango, ubukrelekrele bokufakelwa kunye nokuveliswa kwe-chip, zonke ezo zinto zinokuhlukaniswa nenkxaso yeendawo ezichanekileyo. Uyenza njani into yokufezekisa ukusebenza ngokukuko kunye neendleko eziphantsi zokuvelisa iindawo ezichanekileyo ngumcimbi wokuvelisa oomatshini.

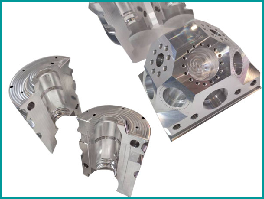

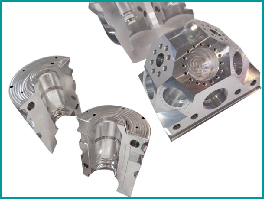

Isiseko sentsimbi

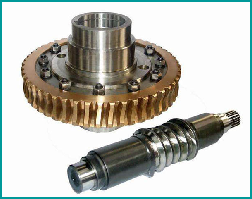

Izixhobo zentshulube

Iindawo ngqo High

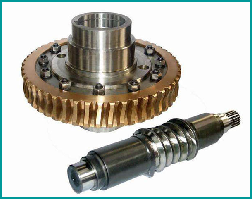

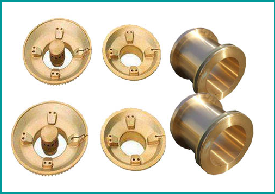

Iindawo Brass

Zingaphi iintlobo zenkqubo machining uyazi?

Precision machining yinkqubo yokutshintsha ubungakanani okanye ukusebenza workpiece ngokusebenzisa umatshini processing. Ngokombuso wobushushu bendawo yokusebenza eqhubekekayo, inokwahlulahlulwa kube kubanda, kushushu kwaye kulungiswe ngokukodwa. Ngokuqhelekileyo iqhutyelwa kwiqondo lokushisa lokulala kwaye ayibangeli ukuba utshintsho lweekhemikhali okanye lomzimba lomsebenzi. Ibizwa ngokuba yinkqubo ebandayo. Ngokubanzi, ukuqhubekeka okanye ngaphantsi kobushushu obuqhelekileyo kuya kubangela utshintsho lweekhemikhali okanye lomzimba kwindawo yokusebenza, ebizwa ngokuba kukuqhubekeka kobushushu. Ukusebenza kubanda kungohlulwa kukusika kunye nokusebenza koxinzelelo ngokungafaniyo kweendlela zokulungisa. Unyango Ubushushu, nasekuqiniseni, bephosa kunye welding ziqhelekile xa kushushu. Ukusika ngokuchanekileyo kuhlala kungumakhonkco wokugqibela wokuqinisekisa ukuchaneka kwamalungu, kwaye ikwayikhonkco kunye nomthwalo omkhulu womsebenzi, owenza ngaphezulu kwe-60% yokuqhubekeka kwamalungu oomatshini.

Yintoni ukusika ngokuchanekileyo komatshini?

Ukucanda oomatshini yeyona ndlela iphambili yokulungisa ngoomatshini, ibhekisa kwinkqubo yokususa izinto ngohlobo oluchanekileyo.

Precision ahlabayo ngoomatshini luhlobo lomatshini processing ngobuciko eliphezulu. Zimbini iindlela eziphambili zokuqonda ukuchaneka ngokuchanekileyo kwamalungu:

(1) Enye kukusebenzisa izixhobo zomatshini ezichanekileyo zokulungisa iindawo ezichanekileyo, ezinje ngokulungelelanisa umatshini okruqulayo, umsonto wentambo, isixhobo sokususa umbungu, isikhuseli segiya, isixhobo sokugaya, inkqubo yokuchaneka kwangaphandle ephezulu umatshini wokwenza ulungelelwaniso lwentambo, njl. njl. Ezi zixhobo zoomatshini zizixhobo ezikhethekileyo zokuchaneka ngokukodwa, ezisetyenziselwa ukuqhubekeka kohlobo oluthile lwenxalenye, ezinje ngegiya, iiturbines, isikrufu, izixhobo zokusika, ishafti yokuhambisa ethe ngqo kunye nebhokisi yeenjini, njl. Ezi zixhobo zomatshini zisebenza ngokufanelekileyo kwaye zichanekile ngokuqhubekeka kwenjongo ekhethekileyo.

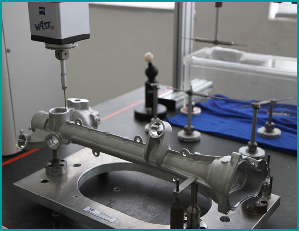

(2) Okwesibini kukusebenzisa itekhnoloji yembuyekezo yempazamo ukuphucula ukuchaneka kokuqhubekeka kwamalungu. Ezona zixhobo ziphambili zomatshini wokulawula ngokubonakalayo ngumatshini wokugaya we-CNC, i-CNC lathe, i-CNC grinder, umatshini we-CNC okruqulayo kunye nomatshini wokugaya.

Izixhobo zomatshini we-CNC zijolise kwizixhobo zomatshini ngokubanzi, ngenxa yokusetyenziswa kwetekhnoloji yenkqubo yekhompyuter, inokucwangciswa kwangaphambili kulungiso lwekhompyuter kunye nokulungisa ingxaki, inokuhambelana okuhle kunye nokuziqhelanisa, kufanelekile kwimilo entsonkothileyo, kwiindawo ezahlukeneyo zokulungisa. Izixhobo zomatshini we-CNC zibiza kakhulu, kodwa ziyakuqonda ukuzenzekelayo kokulungiswa, kwaye zibe nokuchaneka kokuphindaphinda kunye nokusebenza kwemveliso.

Ungasikhetha njani isixhobo esifanelekileyo sokuqhubekeka?

Ngokuphuculwa kwetekhnoloji yolawulo lwekhompyuter, izixhobo ezingaphezulu nangaphezulu zomatshini zidityaniswe nenkqubo ye-CNC, ukwenzela ukuba kufumaneke ukuzenzekelayo kokulungiswa, kuthintelwe iimpazamo zokusebenza ngesandla, kunye nokuphucula ukuchaneka kokusebenza kunye nozinzo. Ke ngoko, izixhobo zomatshini we-CNC zisetyenziswa ngokubanzi kwicandelo lokuvelisa ngokuchanekileyo.

(1) CNC processing ngqo shaft yesinyithi entle iphezulu, kunye nomgangatho processing ezinzileyo;

(2) Inokuqhuba unxibelelwano olunxibelelanisayo kunye neenkqubo zenkqubo ezinemilo engalunganga.

(3) Xa iinxalenye ze-CNC zekhompyuter zitshintshiwe, inkqubo ye-NC kuphela ekufuneka itshintshiwe ukugcina ixesha lokulungiselela imveliso.

(4) Isixhobo somatshini ngokwawo sinokuchaneka okuphezulu kunye nokuqina, kwaye unokukhetha inani elifanelekileyo lokuqhubekeka, kwaye inqanaba lokuphuma liphezulu (ngokubanzi amaxesha ama-3 ukuya kwayi-5 kweso sixhobo somatshini ngokubanzi).

(5) Izixhobo zoomatshini zizenzekelayo kwaye zinokunciphisa amandla abasebenzi.

Ukusebenza kakuhle kwe-CNC kusetyenziswa izixhobo zokusika ezimfutshane yeyona nto iphambili kumalungu e-Hardware. I-cutters ezimfutshane zinokunciphisa kakhulu ukuphambuka kwesixhobo, emva koko zifezekise umgangatho wobuso obalaseleyo, ukunqanda ukuphinda usebenze, ukunciphisa ukusetyenziswa kweentonga ze-welding, kunye nokunciphisa ixesha lokulungiswa kwe-EDM. Xa uqwalasela machining ezintlanu-axis, kuyimfuneko ukuba siqwalasele umgaqo yokusebenzisa-axis ezintlanu processing die: ukugqiba yonke processing workpiece kunye izinto ukusika elifutshane kangangoko kunokwenzeka, kodwa ukunciphisa iinkqubo, nokubotshwa kunye nexesha processing ukufumana umgangatho womgangatho ogqibeleleyo.

Uyenza njani itekhnoloji yokulungisa efanelekileyo?

(1) Inqanaba lokulungisa elibi. Ukuphelisa uninzi lwesibonelelo sokuqhubekeka kwendawo nganye yokuqhubekeka kunye nokuvelisa umlinganiso ochanekileyo, eyona nto ibaluleke kakhulu kukuphucula imveliso kangangoko kunokwenzeka.

(2) Inqanaba lokugqibezela. Susa iziphene ezinokubakho emva kokuqhubekeka okungalunganga, lungiselela ukugqitywa kwembonakalo, kufuna ukufikelela kukuchaneka kokuqhubekeka okufunekayo, qinisekisa isibonelelo sokugqiba esifanelekileyo, kwaye ugqibe ukusebenza komphezulu wesibini kunye.

(3) Inqanaba lokugqiba. Kweli nqanaba, isantya esikhulu sokusika, ukutya okuncinci kunye nobunzulu bokusika kukhethwe ukususa isibonelelo sokugqiba esishiywe yinkqubo engaphambili ukwenzela ukuba ukubonakala kwamalungu kuhlangane neemfuno zobugcisa zemizobo.

(4) inqanaba machining Ultrafine. Isetyenziselwa ukunciphisa ixabiso loburhabaxa bomhlaba okanye ukomeleza ukubonakala kokuqhubekeka. Isetyenziselwa ukujongana nomphezulu kunye neemfuno eziphezulu zoburhabaxa bomhlaba (ra <0.32 um).

(5) isigaba Ultra-ocoliweyo processing. Ukuchaneka komatshini ngu-0.1-0.01 micron kunye nexabiso loburhabaxa be-RA lingaphantsi kwe-0.001 micron. Ezona ndlela ziphambili zokulungisa zezi: ukusika okucokisekileyo, ukugaya isipili, ukugaya nokucola.

Ukhetha njani izinto ezifanelekileyo zomsebenzi?

Ukusebenza ngokuchanekileyo, ayizizo zonke izinto ezingafunekiyo ezinokunqwenela ukuqhubekeka ngokuchanekileyo, ezinye izinto ezilukhuni zinzima kakhulu, zigqitha ubunzima bezixhobo zomatshini wokulungisa, zinokuwa ngamacandelo omatshini, ke ezi zinto ziluhlaza azilungelanga ukuqhubekeka ngokuchanekileyo komatshini, ngaphandle kokuba yenziwe ngezinto ekrwada eyahlukileyo, okanye laser ukusika.

Imathiriyeli ekrwada yokuchaneka ngokuchanekileyo inokwahlulahlulwa ibe ziindidi ezimbini, izinto zentsimbi ekrwada kunye nezinto ezingezizo zesinyithi.

Ngokubhekisele kwizinto zentsimbi ekrwada, ubunzima bentsimbi enomhlwa buphezulu, ilandelwa yintsimbi ebunjiweyo, ilandelwa bubhedu kunye nealuminiyam ethambileyo.

Ukulungiswa kweeseramiki kunye neeplastikhi kungokulungiswa kwezinto ezingezizo zesinyithi.

1. Okokuqala, iinxalenye kufuneka zibe nenqanaba elithile lobulukhuni. Kwezinye izicelo, ukuphakama kobunzima bezinto ezingenanto, kungcono. Kuphela kuphela kwiimfuno zobulukhuni iinxalenye ngomshini. Izinto ezenziwe ngomatshini azinakuba nzima kakhulu. Ukuba zinzima kunezinto ezenziwe ngomatshini, azinakwenziwa ngomatshini.

2. Okwesibini, izinto ziphakathi ngobunzima kunye nokuthamba. Ubuncinane inqanaba elinye lobulukhuni lingaphantsi kunelo leenxalenye zomatshini. Kwangelo xesha, kuxhomekeke ekusebenzeni kwezixhobo ezenziweyo kunye nokukhethwa ngokuchanekileyo kwezinto zomatshini.

Ngamafutshane, kusekho iimfuno ezithile zomgangatho wezinto kwimishini yokuchaneka, ayizizo zonke izinto ezifanelekileyo ekuqhubekekeni, ezinje ngezinto ezithambileyo okanye ezilukhuni, eyokuqala ayimfuneko ekuqhubekisweni, kwaye eyokugqibela ayinakho ukuqhubekeka.

IMestech ibonelela abathengi ngemveliso kunye nokulungiswa kwezahlulo zentsimbi ezichanekileyo. Ukuba ufuna ulwazi oluthe kratya, nceda unxibelelane nathi.