Ukunyathela isinyithi

Inkcazo emfutshane:

Ukunyathela isinyithi kukusebenzisa inqindi kunye nokufa ukukhubazeka kwentsimbi engenasici, i-iron, i-aluminium, ubhedu kunye nezinye iipleyiti kunye nezinto zangaphandle ukufezekisa ubume kunye nobungakanani benkqubo.

Inkqubo bexhentsa zingahlulwahlulwa zibe yinkqubo ngokwahlukana kunye nokwenza inkqubo (kubandakanya ukugoba, ukuzoba kunye nokwakha). Inkqubo yokwahlula ukwahlula indawo yokunyathela kunye nokungabinanto ecaleni komgca othile wenkqubo yokunyathela, kwaye umgangatho wecandelo elahluliweyo lwesahlulo sokunyathela kufuneka uhlangabezane neemfuno ezithile; inkqubo ukuyila kukuba bexhentsa deformation zeplastiki blank phantsi imeko akukho monakalo, uze uyiguqule imilo imveliso ezigqityiweyo, kananjalo ukuhlangabezana neemfuno ukunyamezelana mbini kunye neminye imiba.

* Ngokweemeko zokunyathela ubushushu, zimbini iindlela zokunyathela kubanda kunye nokunyathela okushushu. Oku kuxhomekeke kumandla, iplastikhi, ukutyeba, isidanga se-deformation kunye nomthamo wezixhobo, kunye nemeko yokuqala yonyango lobushushu kunye nemeko yokugqibela yenkonzo ekufuneka ithathelwe ingqalelo. 1. Ukunyathela okubandayo kwesinyithi kubushushu begumbi, ngokubanzi kusebenza kubungakanani obungaphantsi kwe-4mm. Inezinto eziluncedo zokungafudumezi, akukho lusu lwe-oxide, umgangatho osemgangathweni, ukusebenza ngokukuko kunye neendleko eziphantsi. Ukungancedi kukuba kukho umsebenzi onzima, owenza ukuba isinyithi siphulukane nobuchule bokuphambuka. Ubungakanani bento engenanto bufana kwaye akufuneki ekuqaleni. 2. Ukunyathela okushushu isinyithi kufudunyezwe kwinqanaba elithile lobushushu. Izibonelelo kukuba zinokuphelisa uxinzelelo lwangaphakathi, zithintele ukusebenza nzima, zonyuse iiplastikhi, zinciphise ukuxhathisa kwe-deformation kunye nokunciphisa ukusetyenziswa kwamandla kwezixhobo

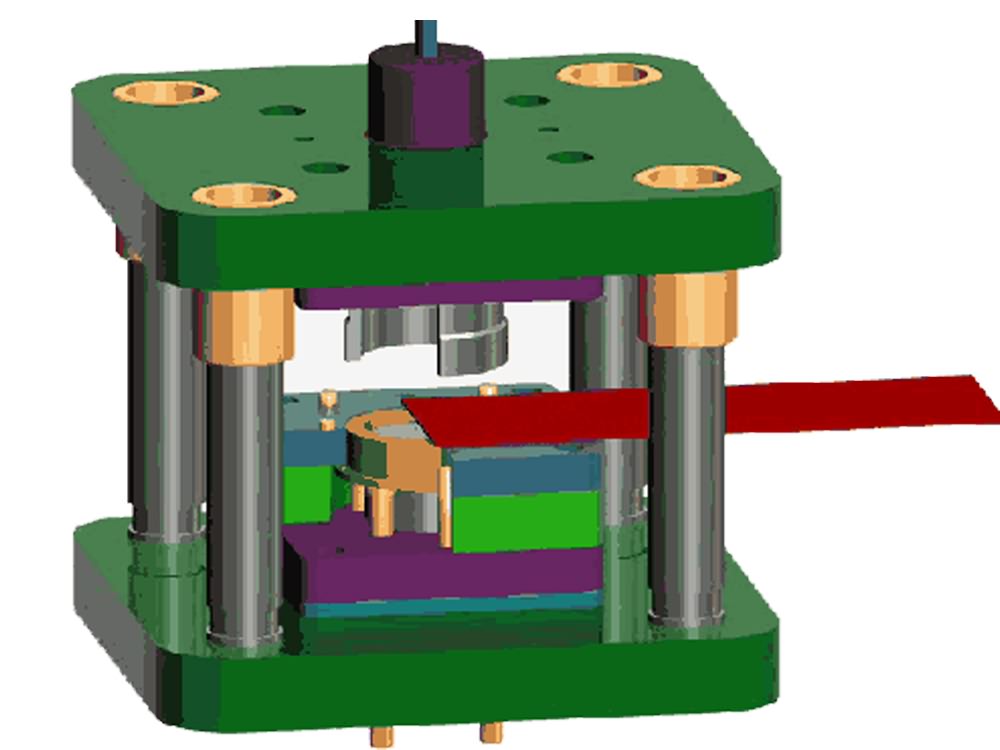

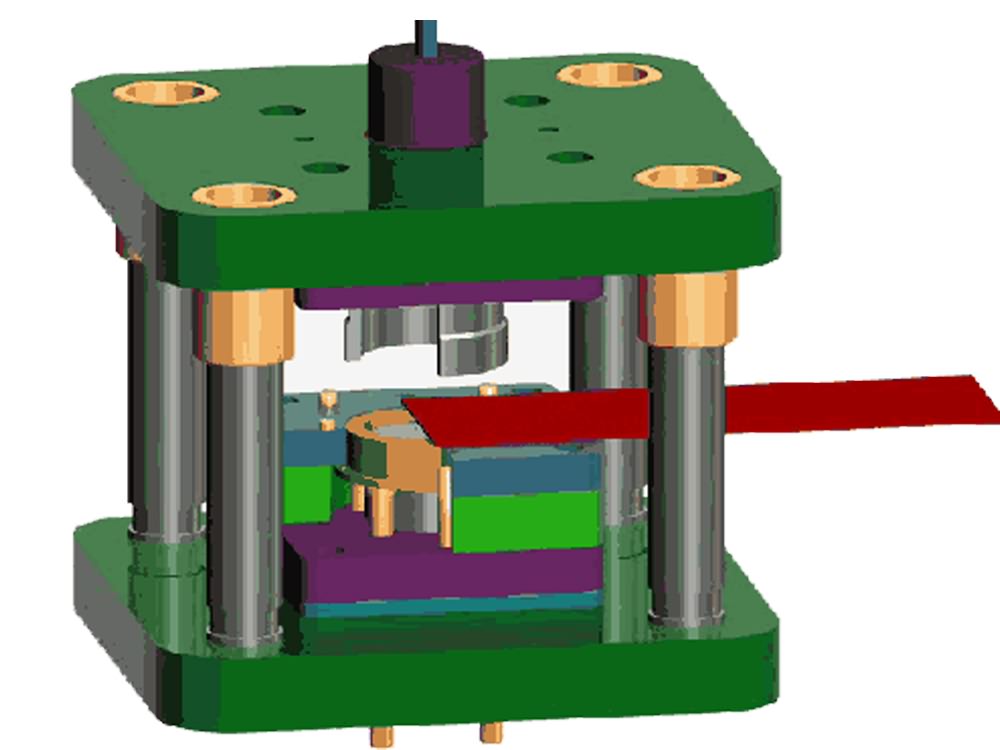

* Izinto ezintathu ezisisiseko zenkqubo yokufaka isitampu: kufa, cofa kunye nephepha lesinyithi

1. Ukubetha i-Die Die yinto ebalulekileyo yokufa kwimveliso yokunyathela. Zintathu iintlobo zokufa kokunyathela: ukusweleka okulula, ukusweleka okuqhubekayo kunye nokufa okuhlanganisiweyo.

I-Die Die yinto ebalulekileyo yokufa kwimveliso yokunyathela. Zintathu iintlobo zokufa kokunyathela: ukusweleka okulula, ukusweleka okuqhubekayo kunye nokufa okuhlanganisiweyo.

(1) Ukufa ngokulula: ukufa okulula kukugqibezela inkqubo enye kwisibetho esinye seendaba. Kufanelekile ukuba imveliso ibhetshi amancinci iindawo imilo elula.

(2) Ukuqhubeka kokufa: ngesibetho esinye somatshini wokushicilela, idiza egqibezela iinkqubo zokunyathela kwiindawo ezahlukeneyo zediza ngexesha elinye ibizwa ngokuba kukufa okuqhubekayo. Die Continuous ilungele ukusebenza eliphezulu imveliso oluzenzekelayo.

(3) Ukufa okuhlanganisiweyo: ngesibetho, kwinxalenye enye yokufa ukugqibezela iinkqubo zokunyathela ngexesha elinye, eyaziwa ngokuba kukufa okudityanisiweyo. Compound die ilungele bexhentsa izahlulo kunye imveliso enkulu nocoselelo eliphezulu.

2. Ukubetha umatshini

Ukunyathela imveliso ikakhulu ipleyiti. Ngokusebenzisa ukungunda, ungenza blanking, Ukuhlukunyezwa, ukwakha, ukuzoba, ukugqiba, blanking ocoliweyo, ekubumbeni, riveting kunye iindawo extrusion, njl, ezisetyenziswa ngokubanzi kwiinkalo ezahlukeneyo. Umzekelo, sisebenzisa iitshintshi, iisokethi, iikomityi, iikhabhathi, izitya, iimeko zekhompyuter, nkqu neenqwelo moya zemijukujelwa Zininzi izinto ezinokuveliswa ngenqindi ngokusebenzisa ukungunda. Zininzi iintlobo zoomatshini bokuhlukumeza.

(1) Amandla oomatshini oshicilelo oomatshini oomatshini bokuchwetheza banesibetho esisigxina, isantya esinokuhlengahlengiswa kunye nemveliso ephantsi. Isantya siphezulu amaxesha ali-180 / min.

(2) cinezela ngamanzi

I-punch hydraulic inokuhlengahlengisa ukubetha kwistampu ngevalve hydraulic ukuphucula imveliso. Esona santya siphezulu sinokufikelela kumaxesha ayi-1000 / min. Ukungancedi kukusetyenziswa kwamandla aphezulu, iimfuno eziphezulu kwindalo esingqongileyo kunye nomsebenzi omkhulu wokugcina ulondolozo.

(3) Ulawulo lwamanani e-turret punch press

Sebenzisa i-servo motor ukuqhuba intloko, imveliso iphezulu, ukuya kuthi ga kumaxesha angama-800 / min. Ukusetyenziswa kwamandla amancinci, ukugcinwa okulula kunye nobukhulu obuncinci. Ke ngoko, isetyenzisiwe.

Ukufakwa kwesitampu esiqhelekileyo sentsimbi, uninzi lwazo lusebenzisa ipunch. Ngokombane owahlukileyo osetyenziswa koomatshini bokushicilela be-hydraulic, kukho oomatshini bokushicilela be-hydraulic kunye noxinzelelo lwe-hydraulic. Uninzi lwazo lusebenzisa oomatshini bokushicilela be-hydraulic, ngelixa oomatshini bokushicilela be-hydraulic besetyenziselwa ubukhulu becala oomatshini abakhulu okanye oomatshini abakhethekileyo. Ngenxa yezibonelelo zayo ezibalaseleyo, i-servo motor punch isetyenziswa ngakumbi nangakumbi.

Izinto 3.Stamping Izinto bexhentsa iindawo ngokubanzi ipleyiti. Izinto ezikhethiweyo zoyilo lwemveliso ziya kudibana nokusebenza kwenkonzo yemveliso, njengokuqina, ukomelela kunye nokuqhutywa kwemveliso. Kwelinye icala, kufanele ukuba ihlangabezane neemfuno zeplastikhi, umgangatho womgangatho kunye nobukhulu benkqubo yokunyathela. Uyilo lolwakhiwo lweenxalenye zokunyathela kufuneka ziqwalasele ngokupheleleyo iimpawu zenkqubo yokunyathela, irediyasi eguqe, umngxuma wokuma, ulungelelwaniso, ukuzoba ubunzulu, njl.njl. nokumelana deformation ephantsi, kwaye kufanelekile bexhentsa ezibandayo. (1). Izinyithi eziyintsimbi: SPCC / SPCD / spce, SECC / SECD / sece, SGCC, sgld, Sus (2). Ingxubevange yeAluminiyam: al1050p, al1100p, al5020 (3). Ingxubevange yobhedu: Pb phosphor bronze, HBS amandla obhedu aphezulu (4). Ingxubevange yeNickro nickel.

* Itekhnoloji yonyango yomphezulu wamalungu okunyathela Emva kokuba isinyithi siqhubekile senziwe kwaye senziwe, kufuneka iguqule umphezulu wesinyithi, uyihombise umphezulu, kwaye uqhubeke utshintshe iipropathi zoomatshini kunye nezomzimba zentsimbi. Le nkqubo ibizwa ngokuba yonyango lwentsimbi. Injongo yonyango lomphezulu wensimbi lwahlulwe ngokwamacandelo amane:

(1) Intle

(2) Ukukhuselwa

(3) Iipropati ezikhethekileyo zomhlaba

(4) Ukuphucula iipropathi zoomatshini, ezinje ngokuxhathisa ukunxiba, ukuthambisa, njl.

* Uhlobo lonyango lonyango lwe-Electroplating (zinc, ubhedu, i-nickel, i-chromium, igolide, isilivere), ukutshiza nge-electrostatic, ukupeyinta ukutshiza, i-electrophoresis, ushicilelo lwesilika, i-anodizing, blackening, passivation

* Ukunyathela i-Sheet yesinyithi kulula ukufezekisa imveliso ephezulu yokusebenza ngoomatshini kunye nokuzenzekelayo kulula ukuyiqonda ngoomatshini kunye nokuzenzekelayo ngokuvelisa okuphezulu; iindawo zokunyathela zinobungakanani obuchanekileyo kunye nokutshintshiselana okuhle; umphezulu ugudile kwaye ugudile, uhlala ungenawo umatshini. Isetyenziswa ngokubanzi kwimoto, isixhobo sombane, isixhobo, ezokubhabha kunye namanye amashishini okuvelisa.

IMestech ikubonelela ngezahlulo zesinyithi iimveliso kunye neenkonzo. Ukuba unesidingo okanye ufuna ukwazi okungakumbi, nceda unxibelelane nathi.