Ukulungiswa kwensimbi (Ukusebenza ngesinyithi), luhlobo lokuqhubekeka kwetekhnoloji kunye nemisebenzi yemveliso yokwenza amanqaku, iinxalenye kunye nezinto ezivela kwizinto zentsimbi.

Amalungu esinyithi asetyenziswa ngokubanzi koomatshini ohlukeneyo nakwizixhobo. Amalungu esinyithi anokuzinza okuthe nkqo, ukomelela kunye nobulukhuni, iimpawu zokumelana neqondo lobushushu eliphezulu kunye nelisezantsi kunye nokuqhutywa, okusoloko kusetyenziswa ukwenza iinxalenye ezichanekileyo. Xa kuthelekiswa namalungu eplastiki, kukho iintlobo ezininzi zezinto zeengxenye zesinyithi, ezinje ngealuminium ingxubevange, ingxubevange yobhedu, zinc ingxubevange, intsimbi, titanium ingxubevange, wemagniziyam ingxubevange, njl, ezineempawu ezahlukeneyo. Phakathi kwazo, i-ferroalloy, i-aluminium alloy, i-alloy yobhedu kunye ne-zinc alloy zihlala zisetyenziswa kakhulu kwimveliso zorhwebo nezoluntu. Ezi zinto zenziwe ngentsimbi zineempawu ezahlukileyo zomzimba kunye neekhemikhali, ulwakhiwo olwahlukileyo kunye nokumila kweetekhnoloji zokwenza iteknoloji yokwenza umohluko omkhulu.

Ezona ndlela ziphambili zokuqhubekeka kwamalungu esinyithi zezi: machining, stamping, ngqo eyahlulayo, umgubo wokunyibilikisa isinyithi, ngenaliti yokubumba.

Machining yinkqubo yokutshintsha ledayimenshini iyonke okanye ukusebenza workpiece ngokusebenzisa uhlobo lwezixhobo ngoomatshini. Ngokwamahluko kwiindlela zokulungisa, inokwahlulwa ibe kukusika kunye noxinzelelo machining. Ukunyathela luhlobo lwendlela yokwenza inkqubo esebenzisa umatshini wokushicilela kunye nokufa ukwenza amandla angaphandle kwiphepha, umcu, umbhobho kunye neprofayili yokuvelisa ukuguqulwa kweplastiki okanye ukwahlukana, ukuze ufumane ubume obufunekayo kunye nobukhulu bendawo yokusebenza (indawo yokunyathela).

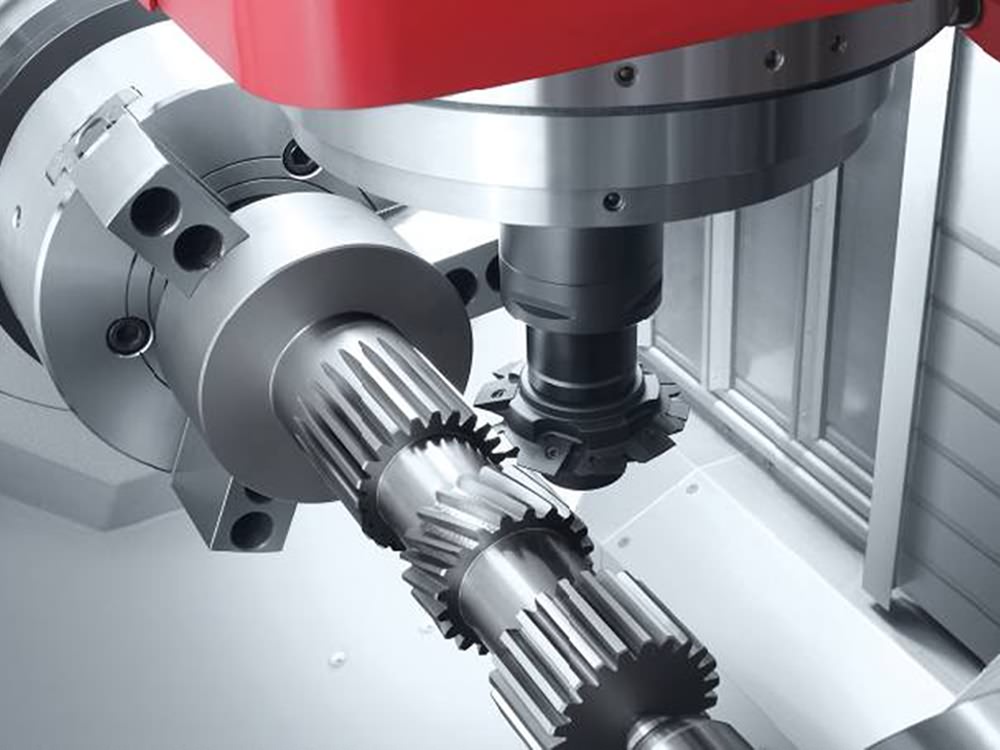

Precision eyahlulayo, umgubo wokunyibilikisa isinyithi kunye nenaliti yenaliti xa ufaka inkqubo eshushu yokusebenza. Zenziwe kumngxunya wokungunda ngokufudumeza isinyithi esityhidiweyo kubushushu obuphezulu ukufumana imilo kunye nobungakanani obufunekayo. Kukwakho nemachining ekhethekileyo, enje: i-laser machining, i-EDM, i-ultrasonic machining, i-electrochemical machining, i-particle beam machining kunye ne-ultra-high speed machining. Ukuguqula, ukugaya, ukubumba, ukulahla, ukugaya, i-CNC machining, i-CNC machining. Zonke zezomatshini.

Izixhobo zoomatshini bokulungisa isinyithi

Izixhobo zoomatshini bokulungisa isinyithi

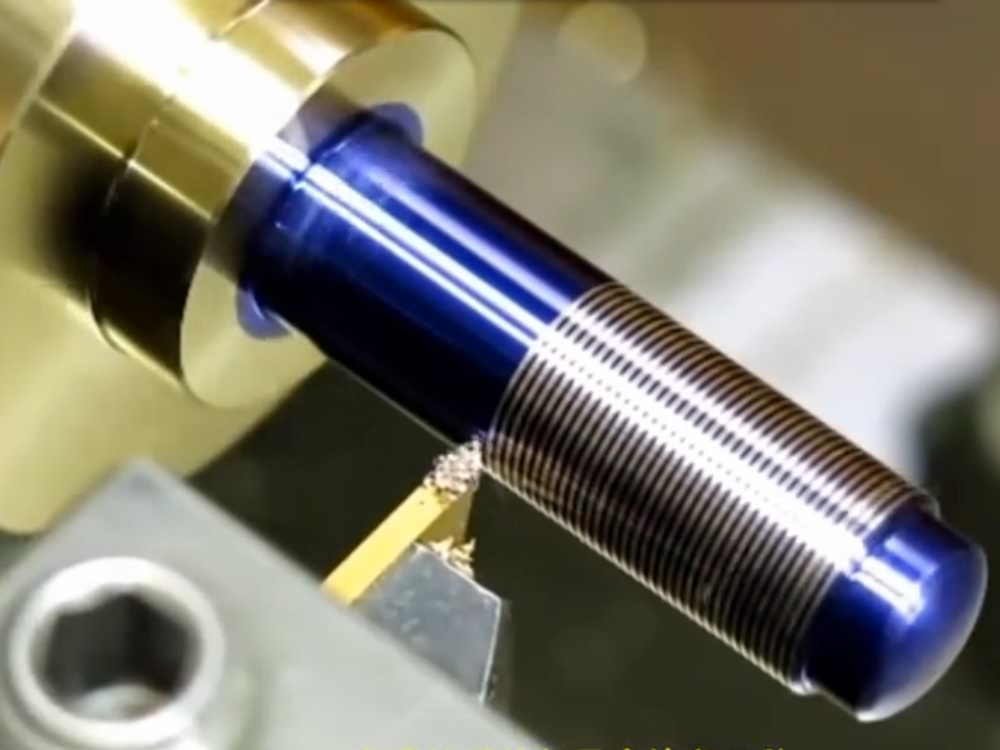

Shaft machining - iziko lathe

Ukuphuma kombane machining -EDM

Precision iqhosha lemenyu machining

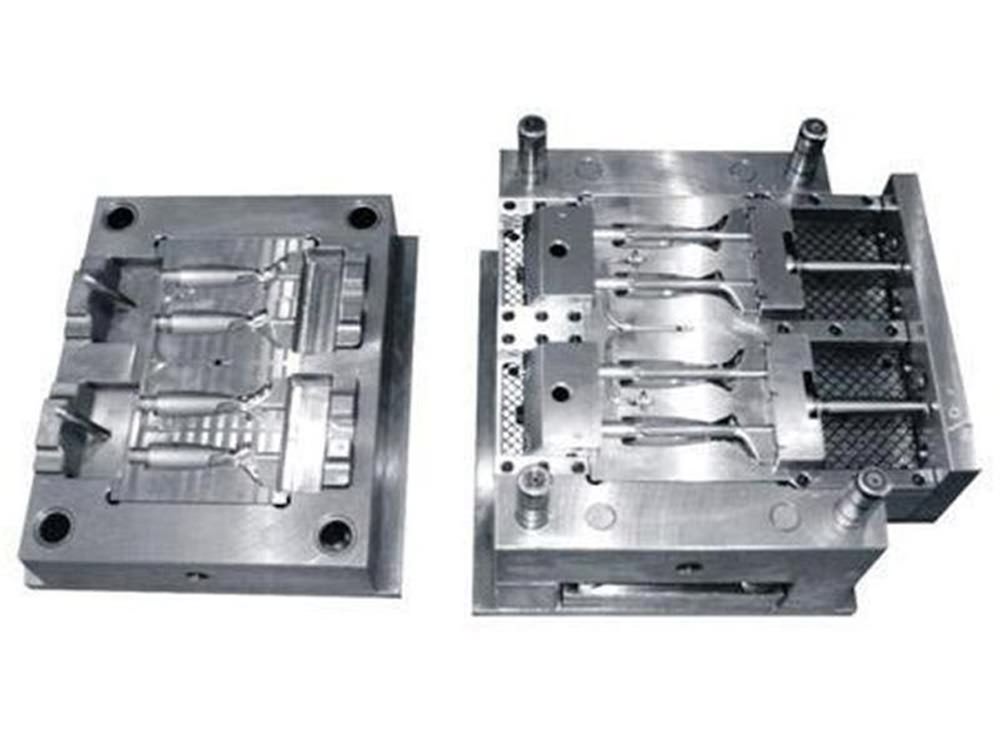

Ukufa umatshini wokuphosa

Die bephosa kufa

Ukubetha umatshini

Ukunyathela die

Bonisa iinxalenye zesinyithi:

1.Izahlulo zentsimbi: iindawo ezenziwe ngentsimbi, i-chromium, i-manganese kunye nezinto zazo ze-alloy.

Precision iindawo sokubumbela

CNC ngomshini iindawo zensimbi

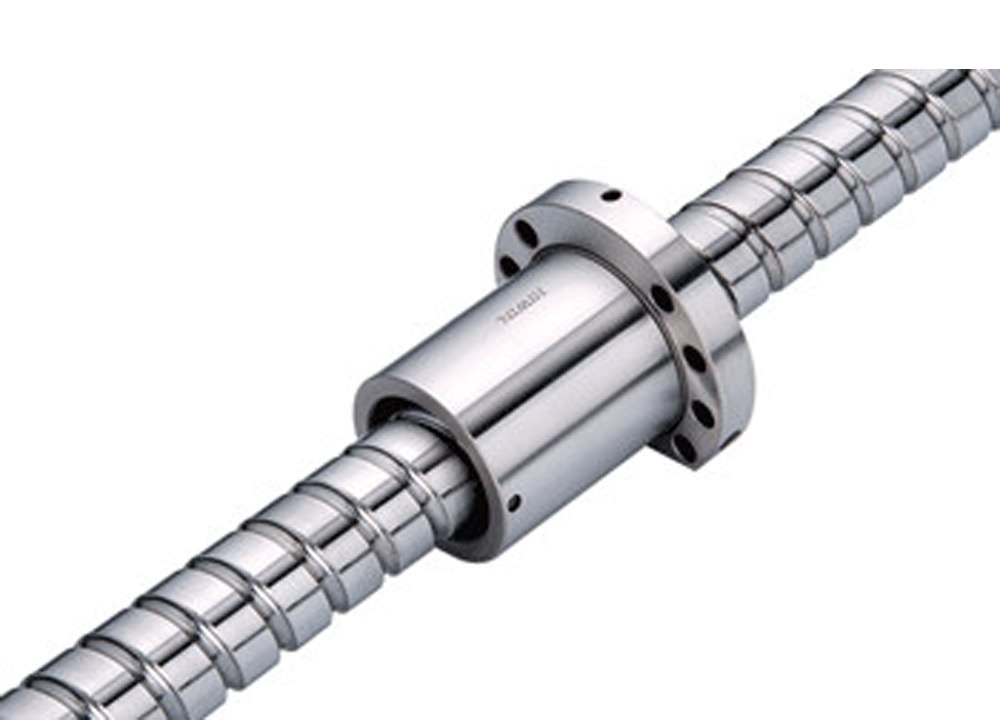

Precision isikhokelo iqhosha lemenyu

Iindawo gear transmission

2.Izinto zesinyithi ezingafakwanga ndawo: iialloys eziqhelekileyo ezingafakwanga isinyithi zibandakanya ingxubevange yealuminium, ingxubevange yobhedu, ingxubevange yemagniziyam, ingxubevange ye-nickel, ingxubevange yetin, ingxubevange ye-tantalum, ingxubevange ye-titanium, ingxubevange ye-zinc, i-molybdenum alloy, i-zirconium alloy, njl.

Izixhobo zobhedu

Izinki ziyafa zilahla izindlu

Isimbozo sokunyathela iAluminiyam

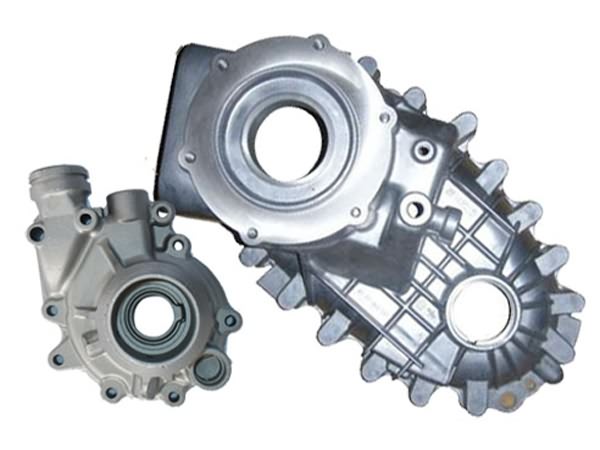

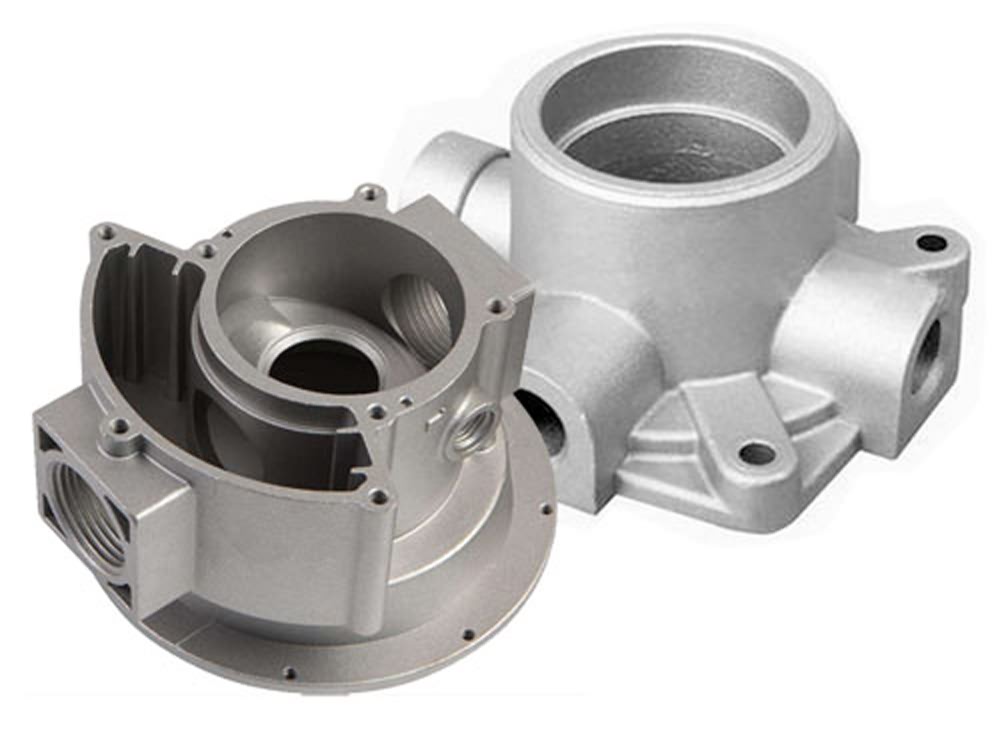

I-Aluminium ifa izindlu zokuphosa

Unyango lomphezulu lungohlulwa lube ngamacandelo amane

1.Unyango lomphezulu womatshini: i-sandblasting, ukudubula imbabala, ipolishi, ukuziqengqa, ipolishi, ukuxubha, ukutshiza, ukupeyinta, ukuthambisa ioyile, njl.

2. Unyango lomphezulu weKhemikhali: i-bluing kunye ne-blackening, i-phosphating, i-pickling, i-electroless plating yesinyithi kunye ne-alloys, unyango lwe-TD, unyango lwe-QPQ, i-chemical oxidation, njl.

3.Unyango lombuso wombane: i-anodic oxidation, ipolishi ye-electrochemical, i-electroplating, njl.

Unyango lwanamhlanje lomphezulu: i-CVD yempembelelo yomphunga wamandla, i-PVD yokufakwa komphunga ngokwasemzimbeni, ukumiliselwa kwe-ion, i-ion plating, unyango lomphezulu we-laser, njl.

IMestech ibonelela abathengi ngoyilo kunye neenkonzo zokuvelisa izinto zentsimbi kubandakanya isinyithi, ialuminium ingxubevange, zinc ingxubevange, ubhedu ingxubevange kunye titanium ingxubevange. Nceda unxibelelane nathi xa kukho imfuneko.