Inkqubo eyahlulayo yokufa

Inkcazo emfutshane:

Inkqubo eyahlulayo yokufa yinkqubo apho i-zinc, ubhedu, i-aluminium, i-magnesium, ilothe, i-tin kunye ne-alloys ye-tin kunye ne-alloys zazo zinyibilike kubushushu obuphezulu kwaye zitofelwe kumngxunya wokubumba, emva koko zipholile phantsi koxinzelelo lokufumana iindawo.

Iqondo lobushushu yokusebenza yesinyithi die die eyahlulayo isezantsi kakhulu kunaleyo yentsimbi eyahlulayo, kwaye izixhobo ezingqinelana nesiseko kunye neemfuno zenkqubo zilula, kwaye zincinci. Imveliso yokuphosa ifa inokufumana umgangatho wobunjani obuhle kakhulu kunye nokuchaneka komlinganiso, ngakumbi ifanelekile kwimveliso esemgangathweni yokuvelisa iindawo ezincinci neziphakathi, ezibonelela ngenkxaso yenxalenye elungileyo kwizinto zombane zangoku, izixhobo zombane, iimoto, izixhobo zonyango, izixhobo kunye nekithen izixhobo. Alloys zesinyithi ezahlukeneyo zinophawu olwahlukileyo kwinkqubo yokuphosa abantu ekufeni. Icandelo labo elincinci kunye noyilo oluncinci luhlukile, iqondo lobushushu liyanyibilika lahlukile, ukugqitywa komphezulu kwahlukile, ke kungcono ukubandakanya iqela lethu leenjineli kwangoko ngexesha lenkqubo yoyilo ukusebenzisa ubuchule bethu kuyilo lokwenza imveliso.

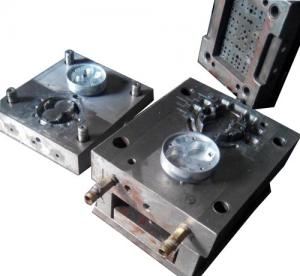

Kukho izinto ezintlanu eziphambili kwinkqubo yokuphosa isinyithi:

Izinto 1.Die eyahlulayo;

Iindidi 2. Inkqubo Die eyahlulayo;

Umatshini 3.Ukuphosa

4.Ukuphosa isikhunta;

Ukucwangciswa kwe-5 kunye nokuGqitywa kweeNxalenye zokuFa

Inkqubo yokuphosa isinyithiyinkqubo yokudibanisa uxinzelelo, isantya kunye nexesha ngokusebenzisa izinto ezintathu zomatshini, ukungunda kunye nealloy. Ukusebenza kwesinyithi kushushu, ubukho boxinzelelo lolona phawu luphambili lwenkqubo yokuphamba yokufa eyahlukileyo kwezinye iindlela zokuphosa. Uxinzelelo ekubunjweni yindlela ekhethekileyo eyahlulayo kunye nokusika okuncinci kwaye akukho ukusika, okuye kwavela ngokukhawuleza kwitekhnoloji yanamhlanje yokulungisa isinyithi. Yinkqubo yokuzalisa ukungunda ngesinyithi esityhidiweyo phantsi koxinzelelo oluphezulu kunye nesantya esiphezulu, kwaye uyilahla ngokufaka i-crystallization kunye nokuqina phantsi koxinzelelo oluphezulu. Uxinzelelo oluphezulu kunye nesantya esiphezulu ziimpawu eziphambili ekubunjweni die. Uxinzelelo olusetyenziswa ngokuxhaphakileyo ngamashumi ee-megapascals, isantya sokugcwalisa (isantya esingaphakathi kwesango) simalunga ne-16-80m / s, kwaye ixesha lokugcwaliswa kolwelo lwesinyithi kumngxunya wokungunda lifutshane kakhulu, malunga ne-0.01-0.2s. I-Metal die casting yinkqubo yokuphosa isinyithi ebonakala ngokunyanzela isinyithi esinyibilikileyo phantsi koxinzelelo oluphezulu kwisisu sokubumba. Isikhunta sokubumba kunye nomongo senziwa sisebenzise i-harden die die eyenziwe ngomatshini kwaye isebenze ngokufanayo ekubunjweni kwenaliti ngexesha lenkqubo. Kuxhomekeke kuhlobo lwesinyithi esiphosiweyo, kusetyenziswa umatshini oshushu okanye obandayo wegumbi.

I-MESTECH inikezela iindawo zokufa zentsimbi, i-aluminium alloy kunye ne-magnesium alloy. Kuba ezi zinto zintathu zezona zisetyenziswa kakhulu xa kusenziwa izinto zokuphosa ingxubevange okwangoku.

Zinc ingxubevange iimpawu:

--- Amandla aphezulu kunye nobulukhuni

--- Ukuqhuba kombane ngokugqwesileyo

--- Ukuqhuba okuphezulu kobushushu

--- Ixabiso eliphantsi lezinto eziluhlaza

Ukuchaneka okuphezulu kunye nozinzo

--- Ukuqaqamba kodonga olucekeceke

--- Amandla kwifom ebandayo, enciphisa ukujoyina

--- Iimpawu zokugqiba umgangatho ophezulu

Ukuxhathisa umhlwa okugqwesileyo-- Ukusebenza kwakhona okupheleleyo

2.Aluminium ingxubevange Iimpawu:

--- Ukushisa okuphezulu

--- nokumelana Outstanding

--- Khaphukhaphu

--- Amandla amahle kakhulu kunye nobunzima

--- Ukuqina okuhle kunye namandla-to-weight ratio

--- I-EMI egqwesileyo kunye ne-RFI yokukhusela iipropathi

--- Ukuqhuba kakuhle kwe-thermal

--- Ukuqhuba kombane okuphezulu

--- Iimpawu zokugqiba ezilungileyo

Ukuhlaziywa kwakhona ngokupheleleyo

3.Iimpawu zeMagnesium Alloy:

Ukuqhuba okuphezulu; zombane, kunye nobushushu

--- Ukuxhathisa amaqondo obushushu aphezulu asebenzayo

Ukuchaneka okuphezulu kunye nozinzo

Ulwalamano olunqabileyo olunqabileyo

--- nokumelana lokusingqongileyo Good

--- Iimpawu zokugqiba ezilungileyo

Ukuhlaziywa kwakhona ngokupheleleyo

1 Inkqubo yokuKhaba okuShushu kwaShushu

Hot-egumbini die eyahlulayo, ngamanye amaxesha ebizwa gooseneck eyahlulayo, yeyona ithandwayo kwezi nkqubo zimbini zokuphosa. Kule nkqubo, igumbi lesilinda lokwenza inaliti ligxile ngokupheleleyo kwibhafu yentsimbi. Inkqubo yesondlo yensimbi ye-gooseneck idonsa isinyithi esityhidiweyo kwi-die cavity.

Ngelixa ukuntywiliselwa ngqo kwibhafu etyhidiweyo kuvumela inaliti ekhawulezileyo kunye elula yokubumba, ikwakhokelela kukonyuka kokudamba. Ngenxa yeli nyani, inkqubo yokuphosa amagumbi ashushu ifanelekile kwizicelo ezisebenzisa isinyithi ngamanqaku aphantsi anyibilikayo kunye nokufuma okuphezulu. Isinyithi esilungileyo senkqubo yokuphosa egumbini elishushu ibandakanya ukukhokelela, i-magnesium, i-zinc kunye nobhedu.

2 Inkqubo yeCold-Chamber die Casting

Inkqubo ekubunjweni egumbini ebandayo iyafana kakhulu ekwenziweni kwegumbi elishushu. Ngoyilo olujolise ekunciphiseni ukubola komatshini endaweni yokusebenza kakuhle kwemveliso, isinyithi esinyibilikisiweyo sizenzekelayo- okanye sifakwe ngesandla kwinkqubo yenaliti. Oku kususa isidingo senkqubo yenaliti yokuntywiliselwa kwibhafu yentsimbi etyhidiweyo.

Kwizicelo ezonakalise kakhulu kuyilo lokuntywiliselwa kwigumbi lokutshisa elishushu, inkqubo yegumbi elibandayo inokuba yeyona ndlela ilungileyo. Ezi zicelo zibandakanya ukulahlwa kwesinyithi ngamaqondo obushushu aphezulu anyibilikayo, anje ngealuminium kunye nealuminium alloys.

3 Inkqubo yoVavanyo oluPhantsi yoFundo

Ukuphosa uxinzelelo oluphantsi yinkqubo efanelekileyo kakhulu kwizinto zealuminium ezilinganayo ezijikeleze i-axis yokujikeleza. Iivili zezithuthi, umzekelo, zihlala zenziwe ngoxinzelelo olusezantsi lokuphosa. Kule nkqubo yenkqubo, isikhunta sime nkqo ngaphezulu kwebhafu yentsimbi etyhidiweyo kwaye siqhagamshelwe ngetyhubhu yes riser. Xa igumbi lixinzelelekile (ngesiqhelo phakathi kwe-20 kunye ne-100kPa), isinyithi sitsalwa sinyukele phezulu kwaye sifumane ukungunda. Ukupheliswa kwe feeders kolu hlobo lwenkqubo yokuphosa ukufa kuhambisa izivuno eziphezulu.

4 Inkqubo yokuFaka i-Vacuum Die

Umshini uxinzelelo eyahlulayo (VPC) yinkqubo entsha yokuphosa umntu eya kufa ehambisa amandla aphuculweyo kunye ne-porosity encinci. Le nkqubo iyafana nokuphosa koxinzelelo oluphantsi, ngaphandle kweendawo ekubunjweni kwazo kunye nokuhlanjwa kwesinyithi kuguquliwe. Igumbi lesilinda linokuba luvavanyo, olunyanzela isinyithi esinyibilikileyo ukuba sibe ngumngundo. Olu luyilo linciphisa isiphithiphithi kwaye linciphisa inani lokufakwa kwegesi. Umshini die eyahlulayo kuluncedo ngokukodwa kwizicelo ezimiselwe unyango emva-eyahlulayo ubushushu.

5 Inkqubo yokuSebenzisa iKhonkco yokuFa

Cudisa ukulahlwa kwenziwa njengesisombululo esisebenzayo sokuphosa isinyithi kunye nealloys ezinobushushu obuphantsi. Kule nkqubo, isinyithi esinyibilikileyo sizalisa into evulekileyo evaliweyo, ethi emva koko icofe ivaliwe, inyanzelise isinyithi kwiindawo ezingapheliyo zokubumba. Inkqubo yokukhipha i-squeeze ihambisa iimveliso ezixineneyo kwaye yinkqubo ehambelanayo kunyango olushushu olulandelayo. Inkqubo ihlala inxulunyaniswa ne-aluminium etyhidiweyo, kwaye isetyenziswa kwizicelo ezifuna ukomeleza ifayibha.

6 Inkqubo yokuPhosa i-Semi-Solid Die

Ukuphoswa kwesemi okuqinileyo, ngamanye amaxesha okubizwa ngokuba yi-Thixoforming, yenye inkqubo ehambisa ubuncinci bokuxinana kunye nokuxinana okuphezulu. Umatshini usika i-workpiece kwii-slugs ezincinci, emva koko ubushushu. Nje ukuba isinyithi sifikelele kutshintsho lwesigaba phakathi kokuqina kunye nolwelo, kukhokelela kulwakhiwo olucekeceke, umkhono odubulayo uyinyanzela kwisibumbeko, apho iqina khona. Izibonelelo zoku ziphuculwe ngokuchanekileyo. Izinyithi ezingenantsimbi ezifana ne-magnesium alloy kunye ne-aluminium alloy zihlala zisetyenziswa kunye nenkqubo yokuphamba yokufa.

7. Iindidi Inkqubo Die eyahlulayo

Zonke iintlobo zenkqubo yokuphosa ziyile zanenjongo enye engqondweni-yenza isikhunta usebenzisa isinyithi esityhidiweyo. Kuxhomekeke kuhlobo lwesinyithi esinyibilikisiweyo, icandelo lejiyometri kunye nenxalenye yesayizi, iinkqubo ezahlukeneyo zokuphosa abantu ezinokuhambisa iziphumo ezingaphezulu kweendlela ezizezinye. Ezi ntlobo zimbini ziphambili zenkqubo yokuphonononga ziyafa kwigumbi elishushu kunye negumbi elibandayo. Umahluko kwezi ntlobo zimbini zokuphosa ukufa kubandakanya:

Low-uxinzelelo die eyahlulayo

Umshini die eyahlulayo

Cudisa ufe bephosa

Iimilo-eqinile die eyahlulayo

Igumbi loxinzelelo olushushu lokufa

Ngokwendlela ebekwe ngayo egumbini, inokwahlulahlulwa ibe ziifom ethe tye kwaye nkqo. Iziko lesinyithi elinyibilikisiweyo liqhotyoshelwe kumatshini ligumbi lokucinezela elishushu, kwaye isixhobo se-piston soxinzelelo lwe-hydraulic engena kwisikhunta sifakwe kwi-crucible. Elinye igumbi lokucinezela elishushu lisebenzisa ii-casters zisebenzisa umoya oxineneyo ukufaka inaliti yoxinzelelo lwentsimbi ngokuthe nkqo kumbumbulu ngaphandle kwendlela yepiston.

Kwigumbi Hot die umatshini eyahlulayo

Igumbi lokucinezela elishushu lila umatshini wokuphosa ubukhulu becala lisetyenziselwa i-die-casting alloy enendawo ephantsi yokunyibilika, njenge-zinc, Magnesium kunye ne-tin.

Igumbi loxinzelelo olubandayo lokufa

Ukunyibilikisa isinyithi ngaphandle komatshini kwaye emva koko ukongeza isinyithi elulwelo kwigumbi lokucinezela ngecephe lingahlulwa libe yindawo ethe nkqo ebandayo yokuphosa umatshini kunye negumbi elibandayo eligudileyo lilahle umatshini ngokokuyalelwa yipiston yoxinzelelo.

Isinyithi eselulwelo sisuswe kwiziko lokubanda lokushicilela elibandayo laza lagalela kwigumbi loxinzelelo. Isinyithi sixineke ngesanti kubunzulu baphantsi sicinezelwe kumbumba yi-compression piston, kwaye i-surplus yentsimbi ikhutshelwa ngaphandle yenye i-piston.

Igumbi Cold afe umatshini eyahlulayo

Igumbi Cold afe umatshini eyahlulayo

Igumbi abandayo tyaba die bephosa umatshini iyafana nkqo, kodwa intshukumo piston tye. Uninzi koomatshini bokuphosa abafayo banamhlanje abathe tye. Oomatshini bokuphosa ababandayo begumbi lokubandayo banokufa-baphose iindawo zokunyibilikisa isinyithi okanye izinyithi ezifakwe lula, ezinje ngealuminium, iiAlloys zethusi, njl

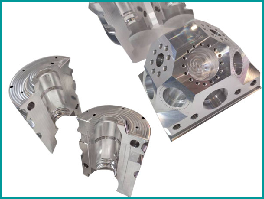

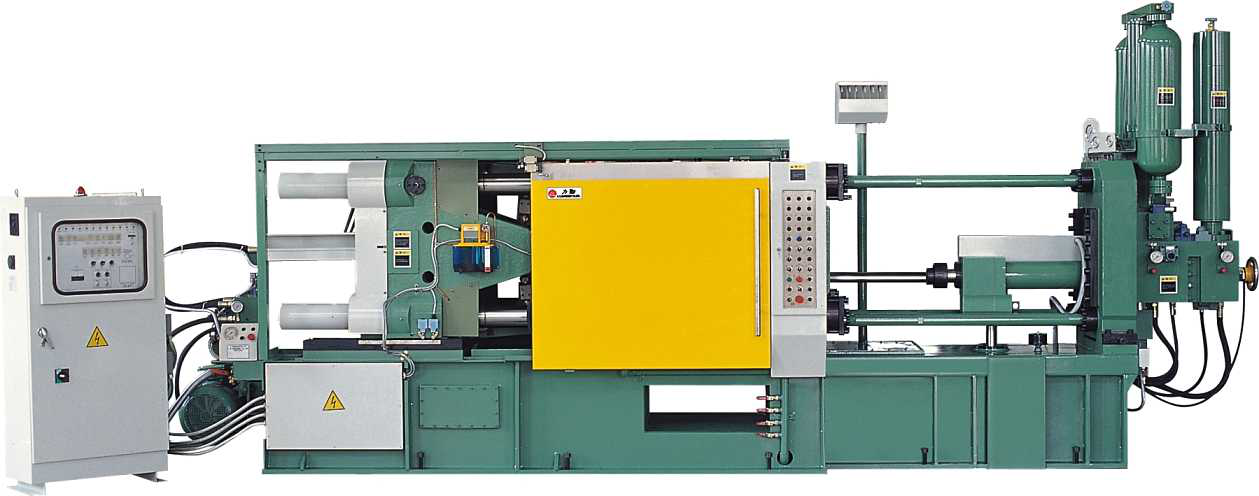

Umatshini bephosa 3.Die.

Umatshini Die ekubunjweni isetyenziselwa umatshini uxinzelelo eyahlulayo. Oku kuquka iintlobo ezimbini eshushu egumbini cofa die bephosa umatshini kunye abandayo ngokucindezela egumbini die umatshini bephosa. Igumbi ngokucinezela abandayo die umatshini eyahlulayo yahlulwe ngokweendidi ezimbini: ngqo tye. Isinyithi esityhidiweyo sitofwe kumbumbulu ngomatshini wokuphosa phantsi kwesenzo soxinzelelo lokupholisa kunye nokwenza, kwaye ukujulwa kwesinyithi okuqinileyo kunokufunyanwa emva kokuba kuvulwe ukungunda.

Kwigumbi Hot die umatshini eyahlulayo

Igumbi Cold afe umatshini eyahlulayo

4.Ukuphosa isikhunta

Xa ngumngundo ezahlukeneyo, iimeko zokusebenza die eyahlulayo die kunokuba nzima. Ukulahlwa kukwenza isinyithi esinyibilikisiweyo sizaliswe ngumngundo ophantsi koxinzelelo oluphezulu kunye nesantya esiphezulu, kwaye uqhakamshelane nesinyithi esishushu rhoqo ngexesha lokusebenza. Ke ngoko, kufa ekubunjweni komngundo kuyafuneka ukuba ube nokukhathala okuphezulu kokudinwa, ukuqhuba kwe-thermal kunye nokunxiba ukunxiba, ukumelana nokubola, ifuthe lokuqina, ubulukhuni obomvu, ukululaza okuhle njalo njalo. Ke ngoko, itekhnoloji yonyango yomphezulu wokufa kokufa ifuna itekhnoloji ephezulu.

Die ekubunjweni ekubunjweni

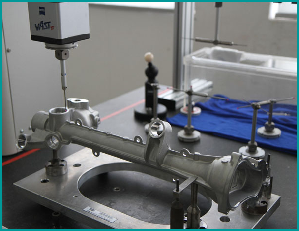

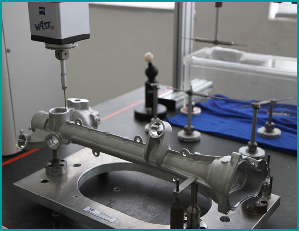

Ukucwangciswa kwe-5 kunye nokuGqitywa kweeNxalenye zokuFa

Sinikezela ngeenkonzo ezininzi zokulungisa kunye nokugqiba iindawo zokufa ezisuka kumaqabane ethu akhethiweyo:

Iinkonzo

CNC machining - nkqo, tyaba, bejika, 5-axis

Ukwaleka kwepowder

Ukwaleka koTywala

Ukukhuselwa kwe-EMI-RFI

Nesingxobo - chrome, ubhedu, zinc, nickel, tin, igolide

Ukwenza i-Anodizing, ukuDibanisa uMbane, ukuChromating / ukungahambisi

Unyango lobushushu, Passivation, Tumbling

Imizobo

Inkqubo yangaphakathi yobugcisa

Uvavanyo lwesilika

Ukuprintwa kwePad

Bead ukuqhumisa

I-Assembly Mechanical Light, kubandakanya i-stud kunye ne-helicoil insert, i-O-ring, i-gasket

Laser Cutting kunye mfanekiso

Ukudibanisa

Ukwaleka kombane kunye noVavanyo lweSilk