Ukwenziwa kweprototype ukwenza isampulu enye okanye ezininzi ngokwendlela yokuyila imveliso okanye ukukhawula, ngeendlela ezithile zokwenza imveliso, ngokweemfuno zokubonakala kwemveliso kunye nokuzoba kwesakhiwo ngaphandle komngundo wemveliso.

Iprototype iphantse yafana nayoyona mveliso ikwimo, umbala kunye nemilo. Isetyenziselwa ukuqinisekisa ukuba ubungakanani bendawo yokudibanisa izinto, imbonakalo, imibala kunye nezinto ezithile ezisebenzayo zeemveliso ezisandula ukuyilwa zichanekile kwaye zinengqiqo, okanye ukubonisa iimveliso kubathengi ukufumana izimvo zabathengi okanye ukwamkelwa kwemakethi.

Imjikelezo yobomi bemveliso iqala kuyilo kwaye iphele kwintengiso. Uyilo lweMveliso luchaza umsebenzi, ukubonakala kunye nokuthembeka kweemveliso. Chonga inkqubo kunye neendleko zemveliso. Uyilo lweMveliso ngumsebenzi ongqongqo, onxulumene nempumelelo kuyo yonke imveliso. Ukusuka kuyilo lwemveliso ukuya kwimveliso yokugqibela yobunzima, naluphi na uhlobo lwemveliso eyenzelwe ukuveliswa kwemveliso kufuneka ityale imali eninzi, ixesha kunye namandla. Uyilo olulungileyo sisitshixo sempumelelo yemveliso. Ukuveliswa kweprototype yemveliso ukuhlalutya, ukuqinisekisa kunye nokuphucula uyilo lwemveliso yindlela ebalulekileyo yokufumana uyilo olugqibeleleyo lwemveliso. Ukuveliswa kwebhodi yezandla kungasiphucula ngokufanelekileyo isantya sophuhliso lwemveliso

Iimveliso zeshishini ngokubanzi, ezinje ngombane, izixhobo zombane, iimoto kunye nezixhobo zonyango, zenziwe ngeplastikhi, ngehardware okanye ngezinto zombane. Ukuthintela inkunkuma enkulu kwimveliso yokubumba kunye nemveliso ebangelwe ziimpazamo zoyilo, senza iisampulu zemodeli ngeendleko ezincinci ngomatshini, ukwenza i-laser kunye nokubumba okwethutyana kunye nezinye iindlela zokuhlalutya, ukuhlanganisa kunye nokuvavanya, okanye ukubonisa abathengi.

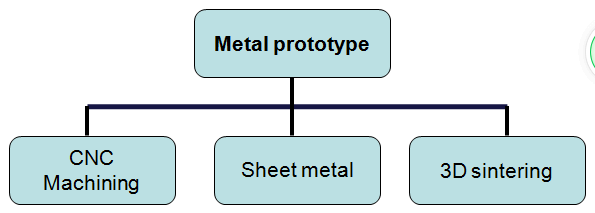

1. Ukuveliswa kwesinyithi ngesandla Imodeli: zintathu iindlela eziphambili zokwenza imodeli yentsimbi

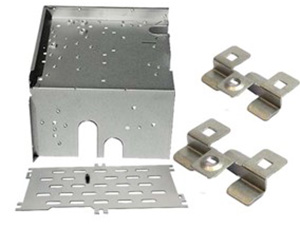

(1). Isinyithi sephepha: ukugoba, ukusika, ukukhupha nokubetha ngesandla okanye izixhobo ezilula. Le ndlela ubukhulu becala esetyenziselwa imodeli ukwenziwa iinxalenye metal obhityileyo-macala. Izinto ezifanelekileyo zibandakanya isinyithi, i-aluminium ingxubevange, ubhedu wobhedu kunye ne-alloy zinc.

(2) i-CNC machining: ukugaya, ukujika, ukugaya, ukukhupha kunye nokugrumba kwezixhobo zesinyithi kwizixhobo zomatshini. Le ndlela isetyenziselwa ukwenziwa kweebhloko kunye neemodeli zesahlulo, ngamanye amaxesha imingxunya okanye ukugqitywa kwasekhaya kweemodeli zetsimbi nazo kufuneka zenziwe ngomatshini. Izinto ezifanelekileyo zibandakanya isinyithi, i-aluminium ingxubevange, ubhedu wobhedu kunye ne-alloy zinc.

(3). Ukuprintwa kwe-Metal laser 3D (isintering): Ukushicilelwa kwe-Metal 3D kusetyenziswa ukuvelisa iinxalenye ezineemilo ezintsonkothileyo kunye nolwakhiwo ekunzima ukuveliswa ngomatshini kunye nokuqhutywa kwesinyithi, okunje ngee-injini, umbhobho wokupholisa imibhobho yamanzi, njl njl. isinyithi kunye nesinyithi seMartensitic, i-titanium engenasici engenanto kunye ne-titanium alloy, i-aluminium alloy, i-nickel base alloy, i-cobalt chromium alloy kunye ne-alloy base alloy

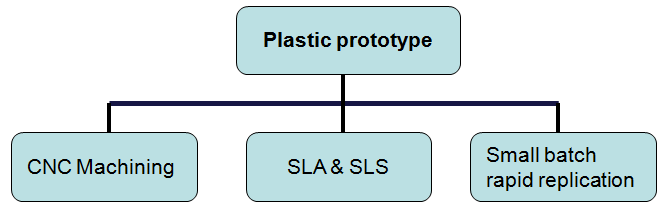

2. Iiprototypes zeplastiki: zintathu iindlela eziphambili zokwenza iiprototypes zeplastiki:

(1) .CNC machining: Oko kukuthi, ezingenanto zeplastiki ngomshini kwisixhobo umatshini. Le ndlela isetyenziselwa ukwenza iigobolondo, ibhloko kunye nomzimba ojikelezayo. Isebenza phantse kuzo zonke izinto zeplastiki ezilukhuni.

(2). Laser 3D yoshicilelo kunye sintering (SLA kunye SLS): SLA isetyenziselwa ukwenza prototype ye iindawo ezintsonkothileyo kunye nokubonakala nzima CNC kunye nesakhiwo, ikakhulu usebenzisa ABS kunye PVC izinto ekuthiwa nentlaka photosensitive. SLS laser bokwakha kwakhona ilungele TPU iiplastiki ezithambileyo ezingenakulungiswa yi-CNC, kunye neeplastiki zobunjineli ezifana nenayiloni.

(3) .Small ibhetshi ukuphindaphindeka ngokukhawuleza yi-silica ye-gel mold (kubandakanya ukuzaliswa kwe-vacuum kunye ne-rim): le nkqubo ithatha imodeli eqhutywe yi-CNC okanye eprintwe yi-laser 3D njengengundoqo, ithululela inani elithile le-silica gel mold, kwaye ijojowe iplastiki engamanzi kwi-silica gel mold mold. Emva kokunyanga, sika i-silica gel mold ukuze ufumane iiplastikhi. Izinto ezisetyenziselwa ukwenza iinxalenye zi-ABS, iPU, iPC, inayiloni, iPOM kunye nePVC ethambileyo

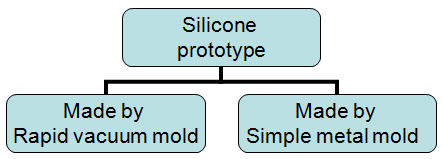

3. Ukwenziwa kweprototype yamalungu e-silica gel:

Izinto zejeli ye-silica ithambile kwaye indawo yokunyibilikisa yobushushu iphantsi kwaye ithambile, ke i-CNC okanye i-laser 3D yoshicilelo ngokubanzi ayifumaneki. Ezona ndlela ziphambili zokwenza abicah prototype kukuthamba komngundo kunye nokwenza ukungunda okulula.

Iiprototypes esizenzele abathengi bethu zezi zilandelayo:

I-CNC Metal prototypes

Amanqaku endlela yesinyithi

Iiprototypes zohlobo lwe-3D

AMAGQABAZA ic abicah yi ngundo ezincamathelayo

Iimpawu zeplastiki ze-CNC

Iimpawu ze-Laser 3D zokuprinta

AMAGQABAZA Plastic zeplastiki ngokugcwalisa emoyeni

AMAGQABAZA ic abicah yi ngumngundo elula bokwakha

Unyango oluphezulu lweprototype

Kuquka 3D yoshicilelo, CNC processing, umphezulu nesingxobo, ukupeyinta kunye isilika screen yoshicilelo lephayiphu replica imodeli inxalenye zeplastiki.

Ukubandakanya iinxalenye zensimbi, ialuminium ingxubevange, zinc ingxubevange, iinxalenye zensimbi imveliso prototype imveliso kunye nokupeyinta, electroplating, igcwala, PVD kunye nezinye unyango komhlaba.

I-Mestech ineqela leenjineli ezijolise kuyilo lwemveliso, zibonelela ngamashishini amancinci naphakathi kunye nabathengi ngeenkonzo zokumisa enye kuyilo lweemveliso, imveliso yemveliso yohlobo, imveliso yeplastikhi kunye nokuveliswa kwesinyithi, inxalenye yemveliso kunye nokuthengwa kwempahla.