Ukufa iindawo zokuphosa

Inkcazo emfutshane:

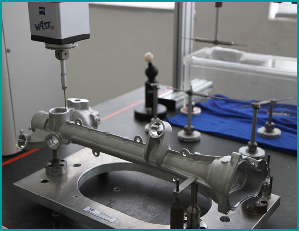

Ukufa iindawo zokuphosa zenziwe nge-zinc, ubhedu, i-aluminium, i-magnesium, ilothe, i-tin kunye ne-alloys ye-tin kunye ne-alloys zazo, ezinyibilike kubushushu obuphezulu kwaye zitofelwe kwisikhunta kwaye zipholile phantsi koxinzelelo

Icandelo lokuphosa isinyithiluhlobo lweendawo zokuphosa uxinzelelo. Luhlobo loxinzelelo ekubunjweni komatshini wokuphosa oomatshini oxhotyiswe ngesixhobo sokuphosa. Isebenzisa isinyithi esifana nobhedu, i-zinc, i-aluminium okanye i-aluminium alloy efudumeleyo ukuya kulwelo lokugalela kwizibuko lokondla lomatshini wokuphosa. Emva die-eyahlulayo ngomatshini die-eyahlulayo, inokuphosa ubhedu, zinc, iindawo zealuminium okanye iinxalenye zealuminium alloy ezinemilo kunye nobungakanani bokufa. Ezo ndawo zihlala zibizwa ngokuba zii-die-casting parts. I-die casting inamagama ahlukeneyo kwiindawo ezahlukeneyo, njengokuphosa amalungu, uxinzelelo lokuphosa, iindawo zokuphosa, i-aluminium yokufa, i-die-casting zinc, i-casting-cast casting, i-copper die-casting, i-zinc die-casting, i-aluminium i-die-casting i-aluminium die-casting, i-aluminium die-casting alloy, i-aluminium ingxubevange yokuphosa iindawo, njl.

Izinto eziluncedo zesinyithi die bephosa iindawo:

(1) Ukuchaneka komlinganiso olungileyo (kuxhomekeke ekubunjweni, kodwa eyokuqala i-2.5cm (0.004 intshi ye-intshi yokuqala) ihlala ingu-0.1mm, 0.02mm kulonyuko ngalunye lwe-1cm (i-intshi engu-0.002 nge-intshi enye inyukile).

(2) Umphezulu ogudileyo (RA 1 - 2.5 microns okanye 0.04 - 0.10 microns). Iindonga ezincinci zingaphoswa xa kuthelekiswa nesanti kunye nokuphosa isigxina (malunga ne-0.75 mm okanye i-0.030 in). Ukufakwa kungafakwa ngaphakathi (umz. Ukufakwa ngemisonto, izinto zokufudumeza kunye neendawo ezinamandla aphezulu). Ukunciphisa okanye ukuphelisa imisebenzi machining yesibini. Isantya semveliso ekhawulezayo. Ukuphosa amandla eqine ukuya kwi-415 MPa (60 Ksi).

Ezingeloncedo yentsimbi die eyahlulayo

(1) Ixabiso lemali liphezulu kakhulu. Xa kuthelekiswa nezinye iinkqubo bephosa, izixhobo ekubunjweni ezifunekayo, ngumngundo kunye nezinye iindawo ezinxulumene nazo zibiza kakhulu. Ke ngoko, ukuze kwenziwe inkqubo yokuphosa ifa kwinkqubo yoqoqosho, inani elikhulu lemveliso liyafuneka.

(2) Ukuhamba kwesinyithi okuphezulu kuphela, ubunzima bokuphosa kufuneka bube phakathi kwe-30 g (1 oz) kunye ne-10 kg (20 lb).

(3) Xa inkqubo standard die eyahlulayo, kuya kubakho isixa esincinci pores xa eyahlulayo lokugqibela. Oku kunokuthintela unyango lobushushu okanye ukuwelda, kuba ubushushu buya kubangela ukwanda kwegesi kwii-pores, eziya kuthi zibangele iintanda ezincinci kunye nokugubungela umphezulu kwiindawo, ngenxa yoko ukungahambelani okunxulumene nokufa kokufa kukuba kusebenza kuphela kwiindawo ezinokuthamba okwamkelekileyo. Icandelo elifuna ukuqina (ngokwenza lukhuni okanye ukuqina kwetyala) kunye nokuqunjelwa akuphoswa kumbumba.

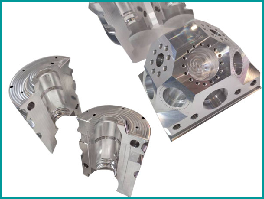

Ukusetyenziswa iindawo ekubunjweni yentsimbi die:

Ngenxa eziluncedo zentsimbi die iindawo eyahlulayo, iye yasetyenziswa ngokubanzi, ikakhulu kwimveliso ubunzima castings ingxubevange non-ayoni. Kwimveliso ye-die-casting, i-aluminium alloy die-casting account yeyona nxalenye inkulu, i-30% -50%; i-zinc alloy die-casting yeyesibini; I-alloy yobhedu yokuphosa iiakhawunti ze-1% -2%. Ezona ndawo zisetyenziswa kakhulu ekubunjweni kokufa ziimoto kunye nokuveliswa kwetrektara, kulandelwa imveliso yezixhobo kunye nezixhobo zecomputer, kunye noomatshini bezolimo, ishishini lokhuselo likazwelonke, ikhompyuter, izixhobo zonyango namanye amashishini okuvelisa. Izahlulo eziveliswa yindlela eyahlulayo yokufa zibandakanya ibhloko ye-injini yesilinda, isiciko sesilinda, ibhokisi yebhokisi yebhokisi, isiciko senjini, iqokobhe kunye nesibiyeli sesixhobo kunye nekhamera, ukudityaniswa kombhobho, izixhobo, njl.

zentsimbi die iindawo ekubunjweni zisetyenziswa:

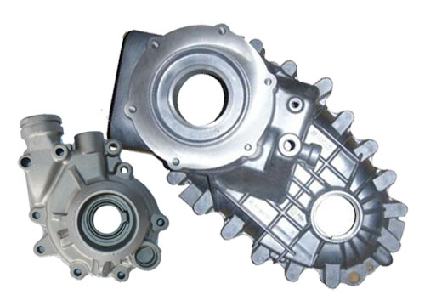

IAluminiyam ifa ikhupha izindlu zemoto

Icandelo lokuphosa i-aluminium yemveliso

I-Auto aluminium ifa izindlu zokuphosa

Izinki ziyafa zilahla izindlu

Zinc die isiseko sokuphosa

Precision Zinc die ekubunjweni izindlu iwotshi

Ukufa ikhamera yezindlu ze-elektroniki

I-Magnesium alloy die casting case / ikhava

Ukufa iindawo zokukhanyisa izibane

I-die-casting valve kunye nempompo yomzimba

Die-ekhupha iinxalenye zokuhombisa

Ukufa iindawo zobhedu

Izahlulo zensimbi zokuphosa izixhobo zinokuveliswa njengezinto zokuphosa imoto, izixhobo zokufaka umbhobho weemoto, izixhobo zokufaka umoya, izinto zokuphosa ipetroli, intloko yokufa, iindawo zokuphosa amandla, ezikhupha iimoto zokugqibela, iqokobhe lokufa, iqokobhe lempompo, izinto zokuphosa izixhobo zokufa, iindawo zokuhombisa zokufa, iindawo zokukhupha ivili zokufa, ivili lokufa kunye nezinye iindawo. Ngokuveliswa kwasekhaya Ngophuhliso lwamashishini ezixhobo, inqanaba lezixhobo zomatshini wokuphinda ufe liphuculwe ngokubonakalayo, iintlobo zeenxalenye ezinokuthi zenziwe ziye zandiswa, kunye nokuchaneka, ukuntsokotha kunye nobungakanani beendawo ezinokuthi zibe Ukufa kwakhona kuphuculwe kakhulu.

Izinto zokuphosa izixhobo zensimbi zisasetyenziswa ngokubanzi kushishino, ngenqwelomoya, ngenqwelomoya, ngenqanawa, ngombane, ngombane kunye nakwezinye izinto zeshishini ngenxa yeenzuzo zazo ezizodwa Ukuba imveliso yakho ifuna ukusetyenziswa, nceda unxibelelane nathi. Siza kukubonelela ngemveliso kunye nenkonzo yentsimbi yentsimbi yokuphosa iindawo ngentliziyo.