Ukwenza umngundo

Inkcazo emfutshane:

Ukwenza umngundo (Ukwenza i-die) yinkqubo yokuvelisa izinto ngokwendlela yokuyila umngundo, usebenzisa ukusika oomatshini, ukuvelisa iintlantsi, unyango lomphezulu kunye nokunyanga ubushushu, kwaye ekugqibeleni ukuhlanganisa onke amalungu abe ngumngundo ngokomzobo woyilo.

Ukwenziwa komngundo kunye nokuvelisa yinto ebaluleke kakhulu kushishino lokuvelisa. Inika izixhobo zenkqubo ebalulekileyo kwizikali ezinkulu, ukusebenza ngokukuko kunye nemveliso esemgangathweni esemgangathweni.

Yintoni ukungunda?

Umngundo (ukungunda, ukufa) ubizwa ngokuba "ngumama weshishini", nto leyo ebalulekileyo kwinkqubo yezixhobo ukufezekisa ukuchaneka okuphezulu, ukusebenza kakuhle kunye nemveliso enkulu kwimveliso yanamhlanje. Ekuveliseni imboni yokubumba, izixhobo ezahlukeneyo zokubumba kunye nezixhobo zisetyenziselwa ukufumana iimveliso ezifunekayo ngenaliti, ukubumba, ukukhupha, ukubumba okanye ukwenza, ukunyibilikisa, ukunyathela kunye nezinye iindlela. Ngamafutshane, ukungunda sisixhobo esisetyenziselwa ukwenza izinto zokubumba. Esi sixhobo senziwe ngamalungu ahlukeneyo, kwaye ukungunda okungafaniyo kwenziwa ngamalungu ahlukeneyo. Ngokukodwa iyakuqonda ukwenziwa kobume bento ngokutshintsha imeko yento ebonakalayo. Yaziwa njenge "mama weshishini".

Yintoni umngundo lemveliso?

Phantse zonke izinto zokubumba zenziwe ngentsimbi, kwaye i-90% yazo yenziwe ngentsimbi.

Ngaphantsi kwesenzo samandla angaphandle, i-billet yentsimbi iba sisixhobo sokwenza imilo ethile kunye nobukhulu. Isetyenziswa ngokubanzi ekunyakeni, ekubumbeni nasekuqiniseni, ekubandeni isihloko, extrusion, umgubo wokunyibilikisa isinyithi ngokucofa, ukuphosa uxinzelelo, kunye neeplastikhi zobunjineli, irabha, iiseramikhi kunye nezinye iimveliso zoxinzelelo okanye inaliti yokubumba. Isibumbeko sinendawo ethile yangaphakathi okanye imilo yangaphakathi, kwaye akukho nto inokuhlulwa ngokobume be-contour (blanking) ngokusebenzisa ubume be-contour ngomphetho. Ubume bomngxunya ongaphakathi bunokusetyenziselwa ukufumana imilo emacala-mathathu e-billet. Umngundo ngokubanzi kubandakanya izahlulo ezibini: ukungunda okususwayo kunye nokubumba okungagungqiyo (okanye ukubetha ngenqindi kunye nomngundo we-concave), onokwahlulwa kudityaniswe. Xa iinxalenye zahlulwe, izithuba ezingenalutho zingeniswe kumngxunya wokubumba xa zivaliwe. Ukubumba sisixhobo esichanekileyo esinemilo entsonkothileyo kwaye sithwele amandla e-bullet. Inemfuno eziphakamileyo kumandla obume, ukuqina, ukuqina komphezulu, umphezulu woburhabaxa kunye nokusebenza ngokuchanekileyo. Inqanaba lophuhliso lwemveliso yokubumba lelinye lamanqaku abalulekileyo kwinqanaba lokuvelisa ngomatshini.

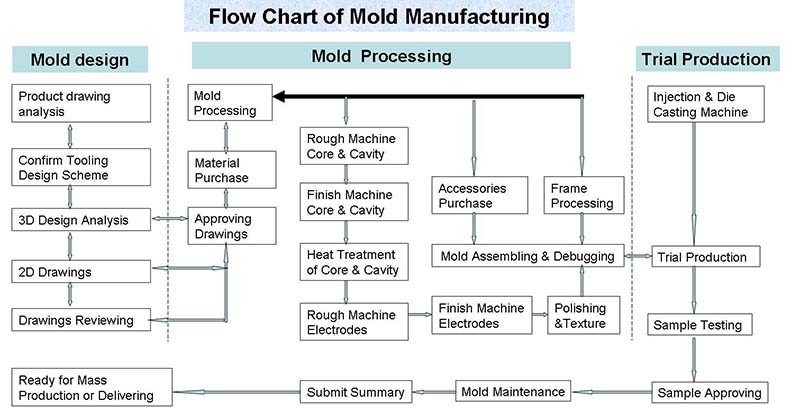

Inkqubo yokuvelisa umngundo ibandakanya: uyilo lwesikhunta, ukuqhubekeka komngundo, ukuhlolwa komngundo kunye novavanyo lokudubula, ukuguqulwa komngundo kunye nokulungiswa, kunye nokugcinwa komngundo.

Ukulungiswa kwemveliso yomngundo kuhlala kufezekiswa, ukusika, unyango lobushushu kunye nendibano kunye nezinye iinkqubo. Ukuqinisekisa umgangatho wokuvelisa ukungunda kunye nokunciphisa iindleko zokuvelisa, izinto kufuneka zibe nokuthamba okungathambekiyo, ukusika ukusasazeka, ukuba lukhuni kunye nokugaya, kwaye kufuneka ubene-oxidation encinci, ubuntununtunu bokwenza decarbonization kunye nokucima utyekelo lokuqhekeka. Ukucanda kuthatha iipesenti ezingama-70 zomsebenzi wokulungisa ukungunda. Elona nyathelo libaluleke kakhulu kukufumana isithuba esihlangabezana neemfuno zobume, ukuchaneka kobukhulu kunye nomgangatho womgangatho, kunye nazo zonke iindlela.

Inkqubo yokubumba

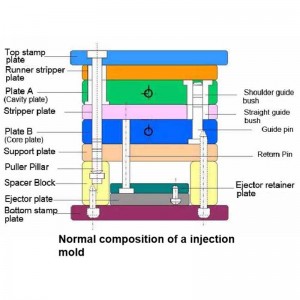

Isinyithi esingenanto sokwenza isikhunta siqengqiwe kwaye senziwe kwisityalo sentsimbi, kwaye isityalo sokubumba sinokukhetha ngokuthe ngqo ukuthenga. Ukwenza umngundo kukwenza ezi ndawo zingenanto zentsimbi zibe ngumngundo onokuthi uvelise iimveliso kwimveliso yobuninzi. Ukuveliswa sokubumba kubandakanya uyilo sokubumbela, machining kunye ibandla ibandla nokuvunda kwaye isiseko sokubumbela.

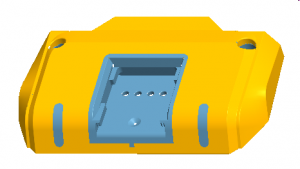

1. Uyilo lomngundo lugqitywa ziinjineli eziqeqeshiweyo. Uyilo zomngundo ngumgangatho kunye nesiseko yonke imveliso ukungunda. Ngokweemfuno zesakhiwo semveliso kunye nokuchaneka komphezulu womhlaba, iimeko zesicelo kunye nemveliso ekulindelweyo, kunye noqwalaselo lomatshini wokubumba inaliti, injineli kufuneka ikhethe ngokufanelekileyo intsimbi kwinxalenye nganye yokubumba kwaye ichonge ubume kunye nenkqubo yokubumba. Ukuhleleka koyilo lokungunda kumisela ubunzima bokuvelisa, indleko, ubomi benkonzo, imveliso kunye nomgangatho wemveliso yokubumba.

Umngundo luhlobo lwezixhobo ezibizayo. Kuyilo, iinjineli zethu zisebenzisa isoftware ukuhlalutya kunye nokulinganisa ukuhanjiswa kwamalungu, indlela yokuhamba, inaliti yenaliti kunye nolwakhiwo lwamalungu.

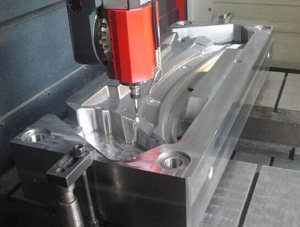

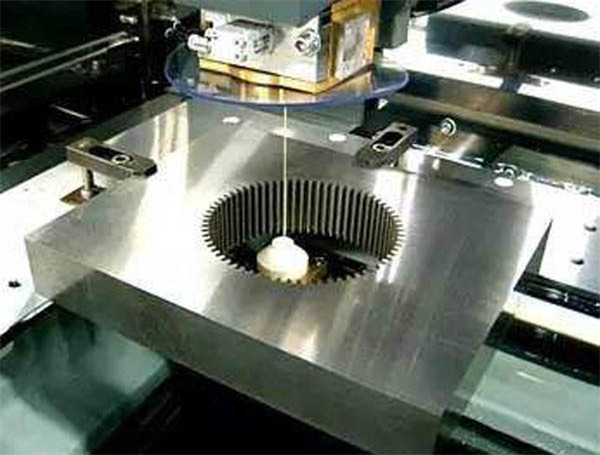

2. Machining sokubumba. I-billet yomngundo iqhutywa ngesixhobo somatshini ngokwendlela yoyilo kunye namaxwebhu enkqubo. Ngokubanzi, izixhobo zomatshini wokusika kunye nezixhobo ezisetyenziselwa ukwenza ukungunda zibandakanya i-CNC, i-EDM, i-WEDM, i-lathe, i-grinder, umatshini wokucoca, njl.Umatshini ophucukileyo kunye ochanekileyo unokuphucula kakhulu ukuchaneka komngundo, unciphise umjikelo wemveliso kunye nokunciphisa iindleko. Iindidi ezahlukeneyo zomngundo zisebenzisa indibaniselwano yezixhobo zomatshini: ukungunda ngenaliti kunye nokufa komngundo kuhlala kusetyenziswa i-CNC, i-EDM kunye neWEDM. Umngundo wokunyathela kunye nezibumba ze-extrusion zihlala zisebenzisa i-CNC kunye neWEDM

3. Indibano yomngundo. Ukuhlanganiswa kwesikhombisi kuxhomekeke kubuchwephesha. Ibandakanya isiseko sokufa, ibhloko yesilayidi, iposti yesikhokelo, indlela yokukhutshwa, ukuthelekisa phakathi kwesakhelo sokufa kunye nemoto, indibano yembaleki eshushu, kunye nenxalenye engenakunqunyulwa, kunye nendibano yokugqibela. Ukunyuka kokuchaneka koomatshini, kokukhona umthwalo womhlangano wokufa, umfutshane umjikelezo wemveliso kunye neendleko ezisezantsi. Emva kokugqitywa kwendibano yediski, kufuneka kuvavanywe, kungqinisiswe, kulungiswe ingxaki kwaye kuphuculwe idiza ide ikwazi ukuvelisa iimveliso ezifanelekileyo nezinye izixa.

Inkqubo yokwenziwa ngumngundo

CNC machining

Ukuchithwa kweMishini ye-EDM-yombane

Ukusika i-WEDM-wire electrode

Lokulinganisa nokuhlanganisa ngumngundo

Inkampani yeMestech ibandakanyeka ikakhulu kwimveliso yokubumba yeplastikhi kunye nenaliti yemveliso, kunye nezixhobo zokubumba zentsimbi (die die-casting die, stamping die) imveliso kunye nemveliso yentsimbi.