Ukuprintwa kwesilkscreen kunye nokuhonjiswa kwepateni yamalungu eplastiki

Inkcazo emfutshane:

Ukuprintwa kwesilkiscreen kunye nokuhonjiswa kwepatheni yinkqubo ebalulekileyo yokuqhubekeka emva kweeplastikhi.

Xa sithengisa iimveliso, ukuze sibonise umsebenzi, ukubonakala kunye nolwazi lwentengiso yeemveliso kubathengi ngexesha elifutshane, ukwenza umbono onzulu, kunye nokutsala abathengi ukuba baqonde kwaye bathenge iimveliso, sihlala sisebenzisa ukuprinta kwesilika, ushicilelo lwephedi, ukukrolwa kwelaser kunye nokunyathela okushushu kunye nezinye iinkqubo zokuprinta okanye ukukrola kumphezulu weemveliso amagama, uphawu lwentengiso oluveza ulwazi ngemveliso, okanye ukongeza iipateni zokuhombisa ngenkangeleko entle.

Umzekelo:

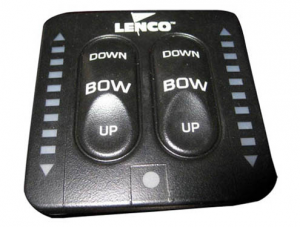

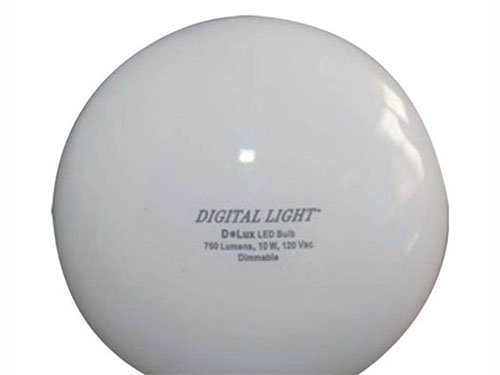

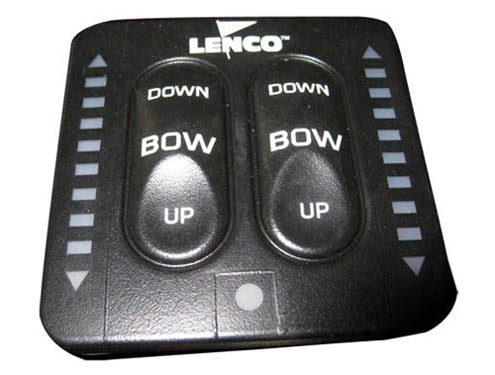

(1) Kwigama lemveliso yokukrola imveliso, chwetheza kunye nenkcazo emfutshane, ukwenzela ukuba abathengi baqale baqonde umsebenzi wemveliso;

(2) Chonga umsebenzi ohambelana kwiqhosha / kwindawo yesalathiso semveliso ukubonisa ukusebenza ngokuchanekileyo.

(3). Phrinta uphawu lwentengiso kunye nolwazi lomenzi kwimveliso ukuze ubhengeze kwaye uphakamise umfanekiso wegama.

Ukushicilela ngaphandle kwemveliso, ukukrola iipateni ezintle zokuhombisa inkangeleko, kunye nokukhuthaza ulwimi ukutsala abathengi.

1. Ushicilelo lwesilikhi

Ukushicilelwa kweSilkscreen yeyona ndlela isetyenziswayo yokuprinta kumphezulu weemveliso zeplastiki. Kufanelekile ukuprinta ipateni kwinqwelomoya.

Xa kushicilelwa, i-inki ithululelwa kwelinye icala lesitya sokuprinta kwesikrini, kwaye isitshisi sisetyenziselwa ukwenza uxinzelelo oluthile kwinxalenye ye-inki yesitya sokuprinta kwesikrini. Kwangelo xesha, i-inki ihamba ngokufanayo isiya kwelinye icala lesitya sokuprinta kwescreen. Ekuhambeni, isishwankathelo sikhama i-inki ukusuka kumngxunya wesahlulo secandelo lomzobo ukuya kwi-substrate.

Imixholo kunye neepateni zokushicilelwa kwesilika kumphezulu wamalungu ziindidi ezahlukeneyo: indibaniselwano yesayizi yokubhaliweyo, ubukhulu be-stroke, umbala ocacileyo, ukukhanya kunye nesimumu, ubume bendawo, ukubonisa ulwazi lweshishini, imveliso, kunye nokwenza iimveliso ezithandekayo ukutsala abathengi, njl.

Ukushicilelwa kweSilkscreen + UV kumalungu eplastiki

Ukushicilelwa kweSilkscreen kumalungu esinyithi

Ukuprintwa okungaphezulu kweMulticolor

Ukuprinta imibala emibini yesilika kwiziciko zeplastiki

Ukushicilelwa kweSilkscreen kubandakanya izinto ezintlanu eziphambili: ipleyiti yokuprinta isikrini, isitshisi, i-inki, itafile yokuprinta kunye ne-substrate. Zimbini iintlobo zesixhobo sokuprinta kwesikrini kumalungu eplastiki okanye kwinyithi: umshicileli wesilika kunye nomatshini wokushicilela wesikrini ngokuzenzekelayo.

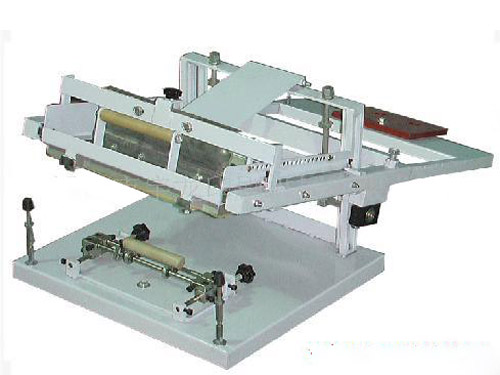

Isishicileli esenziwe ngesandla sesilika sisixhobo esilula. Ayinawo amandla okuqhuba inkqubo yokusebenza, ethi ifezekiswe ngokusebenza ngesandla. Olu hlobo lwesixhobo alulula kwaye alubizi. Iiprinta zesilika ezingezizo ezenziwa ikakhulu zisetyenziselwa umxholo ngokubanzi kunye noshicilelo lwesilikhi yesilika. Ukubonakala komatshini kubonisiwe kumzobo 1 kunye nomzobo 2

Umzobo 1. Isishicileli esenziwe ngesandla sesilika

Umzobo 2. Ukuprinta ngesandla kweSilkcreen

Umzobo 3. Umatshini wokushicilela kwesikrini ngokuzenzekelayo

Umatshini wokuprinta ngokuzenzekelayo wesikrini, onikwe amandla ngumbane, uninzi lwezenzo zokuprinta kwesikrini ziyafezekiswa ngumatshini, njengokulungelelaniswa, ukuxubha, ukuphakamisa njalo njalo. Abaqhubi badlala kuphela indima yokujonga umsebenzi kumatshini, ekuphuculeni kakhulu imveliso, ukunciphisa amandla omsebenzi wabantu. Kwangelo xesha, umshicileli wescreen ozenzekelayo unokufikelela kwimibala emininzi yokuprinta kwesikrini nge-inki efanayo kunye nolungelelwaniso oluchanekileyo. Umshicileli wesikrini esizenzekelayo uboniswa kuMzobo 3.

Ukushicilelwa kwePad

Ukuprintwa kwepad yenye yeendlela ezikhethekileyo zokuprinta. Ingaprinta isicatshulwa, iigrafiki kunye nemifanekiso kumphezulu wezinto ezime ngendlela engaqhelekanga. Ngoku iya ishicilelwa ngokukhethekileyo. Umzekelo, isicatshulwa kunye nephethini kumphezulu weefowuni eziphathwayo zishicilelwa ngale ndlela, kunye nokuprintwa komphezulu weemveliso ezininzi ze-elektroniki ezinje ngeekhibhodi zekhompyuter, izixhobo kunye neemitha kugqitywa ngokudlulisa ukuprinta.

Kuba inezibonelelo ezibonakalayo ekuprintweni kwindawo encinci, imveliso ye-concave kunye ne-convex, yenza iziphene zetekhnoloji yokushicilela kwescreen. Apha ngezantsi kukho iisampulu zamalungu ephedi aprintiweyo.

Ukuprintwa kwepad kumphezulu wegophe

Ukuprintwa kwepad kwindlu yeplastiki

Ukushicilelwa kwepad kwimouse

Ukuprintwa kwephedi yeMulticolor

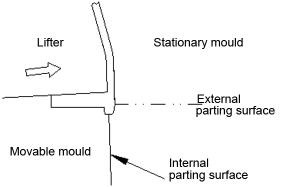

Ukuprintwa kwePad kufuna umatshini wokuhambisa okhethekileyo, ikakhulu owenziwe ngesixhobo seplate (kubandakanya isixhobo sokondla i-inki), i-inki yokutshiza, intloko eyayi-offset (ngesiqhelo izinto ze-silica gel) kunye netafile

Umatshini wokushicilela wephedi ekusebenzeni

3. Ukunyathela okushushu

Ukunyathela okushushu kukwabizwa ngokuba yi-bronzing okanye igolide yokunyathela, kuba isixhobo senziwe ngobhedu. Ukunyathela okushushu yinkqubo yokuprinta kunye nokuhombisa. Isitya sensimbi sifudunyezwa, kuprintwa ifoyile yegolide, kwaye oonobumba begolide okanye iipateni ziprintiwe kwimiba eprintiweyo. Ngophuhliso olukhawulezayo lwefoyile yokunyathela eshushu kunye nomzi-mveliso wokupakisha, ukusetyenziswa kwe-aluminium yombane yokunyathela i-foil kukhula ngakumbi.

Kwinkqubo yokuprinta yeemveliso zeplastikhi, ukunyathela okushushu kunye nokushicilela isilika kulula ukuzisebenzisa kunye neenkqubo zokuprinta ezisetyenziswa ngokubanzi.

Banempawu zexabiso eliphantsi, ukuqhubekeka ngokulula, akukho lula ukuwa, intle kwaye inesisa, kunye nokusebenza ngokutyebileyo. Banokuprinta amagama eenkampani ezahlukeneyo, i-LOGO, ipropaganda, iilogo, iikhowudi njalo njalo.

Ityala leplastikhi enelogo yemibala eshushu

Ukunyathela okushushu kwipatter yokuhombisa kwiphepha leplastiki

Umzekelo wegolide oshushu wokunyathela kwizindlu zeplastiki

Imibala emininzi yeepatheni ezintle ezishushu zokunyathela

Imigaqo kunye neempawu zetekhnoloji yokunyathela igolide:

Inkqubo yokunyathela eshushu isebenzisa umgaqo wokutshintshela ukutshisa okutshisayo ukuhambisa umaleko we-aluminium kwi-aluminium ye-electrolytic kumphezulu we-substrate ukwenza isiphumo esikhethekileyo sesinyithi. Ngenxa yokuba eyona nto iphambili isetyenzisiweyo kwisitampu eshushu yi-electrolytic aluminium foil, inkqubo eshushu yokunyathela ibizwa ngokuba yi-electrolytic aluminium stamping.

Ifoyile ye-Electrolytic aluminium ihlala iqulunqwe ngezinto ezininzi, izinto ezisisiseko zihlala zi-PE, zilandelwa zokwaleka, ukutyabeka umbala, ukutyabeka ngentsimbi (i-aluminiyamu) kunye nokwaleka kweglu.

(1) umphezulu uhombiso unokunyusa ixabiso elongeziweyo leemveliso. Idityaniswe nezinye iindlela zokulungisa ezinje ngebronzing kunye nokucofa i-bump, inokubonisa isiphumo esomeleleyo sokuhombisa imveliso.

(2) Ukunika iimveliso ukusebenza okuphezulu kokulwa nomgunyathi, njengokubeka indawo holographic, ukunyathela okushushu, ukuchonga uphawu lwentengiso, njl.

Emva kokuba imveliso ibronzing, iipateni zicacile, zintle, zinemibala, ziyanxiba kunye nemozulu iyanyamezela. Okwangoku, ukusetyenziswa kwetekhnoloji yebronzing kwiilebheli zecuba eziprintiweyo ngaphezulu kwe-85%. Kuyilo lwegraphic, i-bronzing inokudlala indima ephambili ekuqaqambiseni umxholo woyilo, ngakumbi ukusetyenziswa kokuhombisa kweempawu zorhwebo kunye namagama abhalisiweyo.

Ngentlabo 4.Laser

Ukukrola i-Laser kukwabizwa ngokuba kukrwela i-radium okanye ukumakisha kwe-laser. Itekhnoloji yonyango yomphezulu esekwe kumgaqo wokubonakalayo. Ukukrola i-Laser nayo yinkqubo yonyango yomphezulu, efana nokushicilelwa kwesikrini, ishicilelwe kwiimveliso okanye kwiipateni, kwaye inkqubo yahlukile, ixabiso lahlukile.

Ukukrola i-Laser kudala ipateni ngokutshisa umphezulu womhlaba wenxalenye enobunzima obuthile ecaleni kwendlela emiselweyo kubushushu obuphezulu be-laser. Xa kuthelekiswa noshicilelo lwesilika, inexesha elide ukunxiba kunye nexabiso eliphantsi lokuqhubekeka.

Nangona kunjalo, ngenxa yokutsha kwemathiriyeli yenxalenye yematriki uqobo, ipateni ngumbala omnye, onokwahlulwa ube ziimeko ezimbini:

(1). Icandelo lezinto zokukhanya: umbala omnye ungwevu emnyama;

(2). Kwizinto eziselubala ngokugubungela umphezulu, ipateni iyabonakala emva kwengubo emnyama kwindawo yokutsha. Eli nqaku lihlala lisetyenziselwa ukwenza amaqhosha abalinganiswa abonakalayo.

Ukukrola i-Laser kunokusetyenziswa kumalungu enziwe ngeplastiki, izixhobo zekhompyutha, iinkuni kunye nezinye izinto.

Umgaqo wokulungiswa kwelaser.

(1) Ubunzulu obuphezulu obugxile kwi-laser beam ekhutshwe yi-laser isetyenziselwa ukwenza i-oxidize izinto kunye nokuzilungisa.

(2) Iziphumo zokumakisha kukuveza izinto ezinzulu ngomphunga womhlaba, okanye ukwenza umkhondo wotshintsho lwekhemikhali kunye nolwasemzimbeni ngezinto ezikhanyayo, okanye ukutshisa ezinye izinto ngamandla ombane, kunye nokukrola umkhondo, okanye ukutshisa ezinye izinto ngamandla ombane, ukubonisa imizobo kunye namagama afanelekileyo

Ulwazi Product Product laser

I-laser yomqondiso ikrolwe kwityala leplastiki

Ipateni obalaseleyo laser oqingqiweyo

Ikhowudi ye-QR laser ebhalwe kwimveliso

Umzekelo: ii-keycaps ze-laser

Ukuba ufuna ukwenza ikhibhodi, eneleta okanye inombolo kwi-keycap yayo nganye, enje ngombala oluhlaza okwesibhakabhaka, oluhlaza, obomvu nengwevu, umzimba ophambili umhlophe, ukrola i-laser, ioyile yokuqala yokutshiza, luhlaza, luhlaza, bomvu, ngwevu, nganye fafaza umbala ohambelana nawo, nikela ingqalelo ekubeni ungatshizi kwezinye izitshixo, ukuze kukhangeleke ngathi kukho izitshixo eziluhlaza okwesibhakabhaka, amaqhosha aluhlaza kunye nezinye izitshixo, emva koko ufafaze umaleko omhlophe (okanye omnyama), le yikhibhodi emhlophe yonke, kwaye yonke imisonto eluhlaza naluhlaza isongelwe phantsi kwayo.

Ngeli xesha, i-laser eqingqiweyo ingaqhutywa, kusetyenziswa itekhnoloji ye-laser kunye neemephu zebhodi yezitshixo ze-ID ezenziwe ngefilimu, kukrolwa ioyile emhlophe ephezulu, efana neleta yokuqhubekeka "A", kukrolwa imivumbo emhlophe, emva koko elandelayo okanye eluhlaza okwesibhakabhaka okanye Oluhlaza luya kutyhilwa, ngaloo ndlela kuyilwa iindidi zezitshixo zoonobumba bombala.

Kwangelo xesha, ukuba ufuna ukungafihli nto, sebenzisa iPC okanye iPMMA, ukutshiza ioyile, ukrola inxenye yefonti, emva koko isibane esingezantsi siyakuphuma, kodwa ngeli xesha lokujonga ukunamathela kweoyile ezahlukeneyo, yenza ungafafazi ekuqaleni.

I-Laser ibhalwe ii-keycaps ezingasemva

Ukuprintwa kwe-Silkscreen, ukushicilelwa kwephedi, ukunyathela okushushu kunye nokukrola i-laser ziiposti ezine iinkqubo ezibalulekileyo zokuhombisa ukubonakala kweplastikhi kunye neentsimbi kunye nokuvela kweemveliso. Inkampani yeMestech ibonelela abathengi ngeemveliso zeplastikhi zokubumba kunye nezixhobo zokubumba zehardware kunye nokuprinta kwabo kwesikrini, ukushicilela iphedi, ukunyathela okushushu kunye nokulungiswa kwelaser. Nceda unxibelelane nathi ukuba ufuna ukwenza le mveliso.