Iingcebiso malunga nokuyila kweeplastiki kunye nokubumba

Inkcazo emfutshane:

Precision iindawo zeplastiki uyilo kunye ziphene sukube kufuneka iqale kwizixhobo, uyilo lwamalungu, uyilo lokungunda kunye nokusebenza, umatshini wokubumba inaliti, ukusebenza ngobuchule kunye nemeko-bume yemveliso elungileyo.

Ngokuphuhliswa kweshishini langoku, zininzi izinto ezibonakalayo zeplastiki. Kwangelo xesha, iimveliso zeplastiki zikwasetyenziswa ngokubanzi kwimizi mveliso eyahlukeneyo. Ngokukodwa, iinxalenye zeplastiki zichanekile ngakumbi. Ngoku makhe sabelane nawe ngeengcebiso malunga noyilo oluchanekileyo lweplastiki kunye nokubumba.

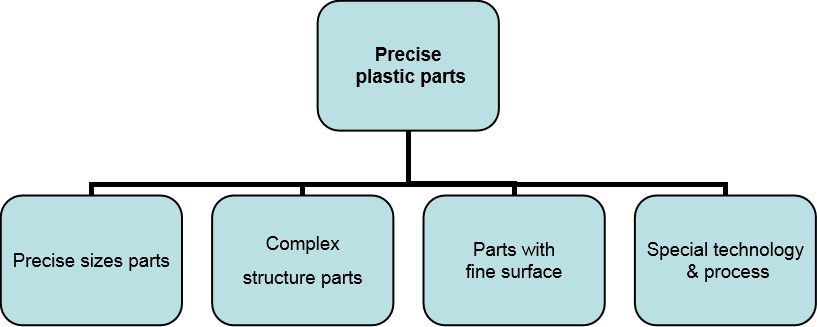

Ucalulo ngokuchanekileyo

iinxalenye zeplastiki:

1. Uyilo lweeplastiki ezichanekileyo

(1) Iindidi zeendawo zeplastiki ezichanekileyo

A. Amalungu aphezulu okuchaneka komlinganiso, afana: neegiya zeemoto, amagiya eentshulube, izikrufu, iibheringi. La malungu achanekileyo ahlala esetyenziswa kwinkqubo yokuhambisa oomatshini (ezinje ngeeprinta, iikhamera, izixhobo zokucoca ngokuzenzekelayo, iirobhothi, izixhobo zombane, ii-UAV ezincinci, njl. Ifuna ulungelelwaniso oluchanekileyo, intshukumo egudileyo, ukuhlala ixesha elide kunye nengxolo.

B. iindawo ezibiyelweyo:

Ngokwesiqhelo, udonga lwamalungu eplastiki luye ngaphantsi kwe-1.00mm, eyeyamalungu obhityileyo. Iindawo ezinqatyisiweyo zingenza ubungakanani bemveliso buncinci kakhulu. Kodwa iinxalenye zeplastikhi ezinqatyisiweyo azinakugcwaliswa ngenxa yokupholisa ngokukhawuleza kunye nokuqina. Kwaye iinxalenye ezibhityileyo-ezinqatyisiweyo azikwazi ukumelana namandla esifa kunye nokwaphuka kumngxunya wokufa. Ke ngoko, uyilo lweenxalenye ezinqatyisiweyo kufuneka zikhethe izixhobo ezineempawu ezingcono zoomatshini. Uyilo olusengqiqweni, olufana nobukhulu bodonga olufanayo, iinxalenye azinakuba ludonga kakhulu. Ukufa okunzulu, ikona enkulu. Kuba amanye amalungu ultra-ezingcakacileyo, ngesantya esiphezulu-ziphene umatshini yokubumba iyafuneka.

C. iindawo Optical:

Iindawo ezibonakalayo zifuna ukuhanjiswa okuhle / ukukhanya kokusebenza kokukhanya, kunye nokuzinza okuhle kunye nokunxiba. Umzekelo, ukugoba komphezulu wee-concave kunye ne-convex lenses ezisetyenziswe kwiiprojektha kufuna ukuchaneka okuphezulu kunye nozinzo. Iiplastikhi ezibonakalayo eziphezulu ezifana ne-PMMA ziyafuneka. Kwangelo xesha, ezinye iindawo zokukhanyisa ezibonakalayo kufuneka zenze imigca ecolekileyo kumphezulu weendawo ukwamkela ukukhanya okanye ukukhanya okanye ukuphelisa ilitha.

D. Umphezulu-isilungiseleli seglosi:

Iindawo ezinobungakanani obuphezulu zibandakanya iindawo ezibonakalayo, kunye namanye amalungu afuna ukugqitywa komphezulu ophezulu (isipili umphezulu). Olu hlobo lwamalungu lusetyenziswa ngokubanzi kwiimveliso zabathengi zombane, ezinje ngeqokobhe lefowuni ephathekayo. Uyilo lolu hlobo lweemveliso kufuneka luqwalasele izinto zeplastiki ezinobushushu obulungileyo, uyilo lobunzima kunye netekhnoloji yokufa.

E. iinxalenye zeplastiki manzi

Uninzi lweemveliso zombane kunye nezombane zifuna ubungqina bamanzi, ezinje ngeglasi / iiwotshi ezingangeni manzi / izixhobo zombane zomkhosi, iimveliso zangaphandle kunye nezixhobo ezinendawo emanzi. Ezona ndlela ziphambili zokungangenwa kwamanzi ziimpawu ezifihliweyo kumgangatho ongaphandle wemveliso, ezinje ngezitshixo ezivalelweyo, iijeki ezivalelweyo, ukutywina imijelo, iwelding ye-ultrasonic, njl.

I-FIMD / i-IML (kwi-mold-jewelry-in-label-in-label)

Le nkqubo ukubeka ifilimu ye-PET kwindawo yokufaka inaliti kunye nokudibanisa iinxalenye zenaliti kubuchwephesha bokuqhubekeka, obuza kunamathela ngokuqinileyo kwiindawo zeplastiki. Iimpawu zeemveliso ze-IMD / ze-IML: ukucaca okuphezulu, istereoscopic, ayisoze yaphela; ukucaca kweefestile zefestile eziphezulu njenge-92%; ukunxiba okunganyangekiyo kunye nokukhusela okunganyangekiyo ixesha elide lenkonzo; Ukuqaqamba kweemveliso eziphambili ngexesha lokufakwa kwenaliti, ubomi obuphambili bunokufikelela ngaphezulu kwesigidi esinye samaxesha.

Inxalenye yodonga lweplastikhi encinci

Iphaneli yeplastiki ye-IMD / IML

Iindawo zeplastiki ngqo

Inxalenye ebonakalayo / ikhava ebonakalayo

Ityala Inaliti kabini manzi

Ityala elichanekileyo leemveliso ze-elektroniki

Izindlu ezinesakhiwo esimbaxa

(2) .Iingcebiso kuyilo ngqo iinxalenye zeplastiki

A. ubukhulu bodonga obufanayo Kwinaliti yokubumba, iplastikhi ikwimeko yolwelo ixesha elifutshane kakhulu, kwaye ukufana kobukhulu bodonga lwamalungu kunefuthe elikhulu ekuhambeni kwesantya nakwicala leplastikhi. Ubukhulu bamalungu butshintsha kakhulu, obuya kuzisa uthotho lweziphene ezinje ngokugcwalisa ukungoneliseki, ukuswakala, ukuncipha, amanqaku e-weld, amanqaku oxinekileyo kunye noxinzelelo, njl.Ngoko ke, udonga lobukhulu beeplastikhi ezichanekileyo kufuneka lube ngokufanayo kunokwenzeka kuyilo. Utshintsho lobunzima akufuneki lube lukhulu kakhulu, kwaye ithambeka okanye utshintsho lwe-arc kufuneka lwenziwe kutshintsho.

B. nikela ingqalelo kulungelelwaniso phakathi kwamacandelo kwaye wenze ubungakanani obufanelekileyo bokuchaneka kobungakanani. Ukuqinisekisa ukutshintshiselana phakathi kwamacandelo, sihlala sinika iimfuno ezingqongqo zokuchaneka kwamalungu ngamanye. Kodwa iinxalenye zeplastiki, ukuba bhetyebhetye ezithile kwaye luthambe. Ngamanye amaxesha, ukuba uyilo luyimfuneko, ukuphambuka kunokulungiswa kukudibana phakathi kwamalungu, ke umgangatho wokuchaneka unokukhululeka ngokufanelekileyo ukunciphisa ubunzima bokuvelisa. Isidanga.

C. ukhetho lwezinto Zininzi iintlobo zezinto zeplastiki, kwaye ukusebenza kwazo kuyahluka kakhulu. Kwizinto zeplastiki ezichanekileyo, izixhobo ezinokuncipha okuncinci / ukuguqa / uzinzo oluhle / ukumelana nemozulu elungileyo kukhethwe ngokweemfuno zokusetyenziswa. (a) I-ABS / i-PC ene-shrinkage esezantsi isetyenziselwa ukubuyisela i-PP ngokuncipha okuphezulu, kunye ne-PVC / HDPE / LDPE ene-shrinkage esezantsi. I-ABS + GF isetyenziselwa ukubuyisela i-ABS.PC + GF ngePC. (b) Khetha i-PA66 + GF okanye i-PA6 + GF endaweni ye-POM okanye i-PA66 ne-PA6.

D. qwalasela ngokupheleleyo inkqubo yokubumba.

(a) Kwigobolondo lobukhulu obuqhelekileyo, ibhokisi okanye iinxalenye zediski, kungcono ukuyila i-microstrip arc kumphezulu kunye nokuqiniswa kwangaphakathi ukunqanda ukusilela.

(b) Kwizinto ezinamacala amxinwa, ubungqingqwa bamalungu kufuneka bube ngokufanayo, kwaye amalungu angaphakathi akufuneki abe neembambo ezomeleza okanye izakhiwo ezintsonkothileyo. Kuyacetyiswa ukuba usebenzise isantya esiphezulu umatshini ziphene yokubumba.

(c) Imilomo eshushu okanye imingxunya yembaleki eshushu isetyenziselwa iindawo ezinkulu ukwenza ixesha lokuzalisa kunye nokunciphisa uxinzelelo kunye nokusilela.

(d) yamacandelo amabini enziwe ngezinto ezimbini, inaliti yombala endaweni yenaliti yeglue yamkelwe.

(e) Kucetyiswa ukubunjwa kwenaliti nkqo ngenxalenye yokufakwa kwesinyithi esincinci.

E. Unendawo yokuphucula. Kuyilo lweeplastiki ezichanekileyo, kufuneka kuvavanywe ukuphambuka okunokwenzeka kwimveliso yexesha elizayo.

(3) Uyilo lokuqinisekisa

Inaliti yokubumba ineendleko eziphezulu, ixesha elide kunye neendleko eziphezulu zokuguqulwa, ke emva kokugqitywa kwesiseko koyilo, kuyimfuneko ukwenza iisampulu zomzimba ukuqinisekisa uyilo, ukumisela ubungqingqwa beeparameter zoyilo lwemveliso, fumana iingxaki kunye nokuphucula ngaphambili.

Uyilo loqinisekiso lomzimba ikakhulu lwenziwa ngokwenza imodeli yohlobo oluthile. Zimbini iintlobo zokwenza iprototype: ukuqhubekeka kwe-CNC kunye nokuprintwa kwe3D

Ukusetyenziswa kweprototypes yokuqinisekiswa komzimba kufuna ingqalelo kwezi zinto zilandelayo:

Iindleko zokuvelisa i-A.CNC zeendleko zemveliso ngokubanzi ziphezulu kunokushicilelwa kwe-3D. Amalungu amakhulu, iindleko ze-CNC processing ziphantsi kakhulu.

Kwizixhobo kunye neepropathi zoomatshini okanye unyango lomphezulu kunye neemfuno zebandla, kuyacetyiswa ukuba kusetyenzwe nge-CNC, ukuze kufumaneke amandla oomatshini. Kwisayizi encinci kunye namandla asezantsi, kushicilelwa i-3-D. Ukuprintwa kwe-3-D kuyakhawuleza, kwaye kubiza kakhulu kumalungu amancinci.

B. Iiprototypes zinokuqinisekisa ngokubanzi ukuhambelana kwendibano phakathi kwezahlulo, jonga iimpazamo zoyilo kunye nokushiya, kwaye uququzelele ukuphuculwa koyilo. Nangona kunjalo, prototype ayinakubonakalisa ngokubanzi iimfuno zeteknoloji yokubumba, njengokuyila i-angle / shrinkage / deformation / fusion line njalo njalo

2. iindawo zeplastiki ngqo sukube

(1) uyilo sokubumbela lweplastikhi (uyilo lwesikhunta) Ukubumba okumgangatho ophezulu sisitshixo sokwenza iindawo ezichanekileyo. La manqaku alandelayo kufuneka alandelwe.

A. ngokuchanekileyo khetha ulungelelwaniso lokunciphisa izinto zeplastiki. Isikhundla esinengqiqo samalungu kumngundo.

B. izinto zokubumba ezingumbindi ziya kukhethwa njengezinto zentsimbi ezinokuzinza / ukunxiba ukumelana / ukumelana nokumelana.

Inkqubo yokuxheshwa kwesikhunta isebenzisa iTsui eshushu okanye imbaleki eshushu kangangoko kunokwenzeka, ukuze iinxalenye zecandelo ngalinye lobushushu zifane, zinciphise ukujika.

D. ukungunda kufuneka kube nenkqubo efanelekileyo yokupholisa ukuqinisekisa ukuba iinxalenye zipholile ngokulinganayo ngexesha elifutshane.

E. umngundo kufuneka ubenelokhi esecaleni nezinye izixhobo zokubeka.

F. ngokufanelekileyo usete indawo yokukhutshwa kwendlela yokuyekisa, ukuze amandla okukhutshwa kwamalungu afane kwaye angakhubazeki.

Uyilo lomngundo kunye nohlalutyo isixhobo esibalulekileyo (i-moldfow): Usebenzisa isoftware yokulinganisa yenaliti xa uxelisa umphumo wenkqubo yokubumba yenaliti phantsi kweeparamitha zokumisela ezahlukeneyo, fumana iziphene kuyilo lwemveliso kunye noyilo lokungunda kwangaphambili, ukuphucula nokuzilolonga, kwaye ukunqande iimpazamo ezinkulu ekuveliseni ukungunda ukuya kuthi ga kwinqanaba elikhulu, elinokuqinisekisa kakhulu umgangatho wokungunda kunye nokunciphisa iindleko kamva.

(2) qinisekisa ukungunda.

Iindleko zokubumba ezilula ziphantsi kakhulu kunaleyo yokubumba. Amalungu zeplastiki ngenaliti ngqo, kufuneka wenze ukungunda elula ukuqinisekisa uyilo sokubumba ngaphambi kokwenza imveliso yokubumba esemthethweni, ukuze ufumane iiparameter zokuphucula uyilo lwesikhunta kunye nokuqinisekisa impumelelo yokubumba kwemveliso.

(3) processing sokubumba

High ekubunjweni kufuneka ngomshini kunye aba matshini zilandelayo eliphezulu ngqo.

A. ngqo eliphezulu umatshini CNC

B. umatshini obengezelayo

C. ukunciphisa ucingo

D. indawo yokusebenza ngokushisa rhoqo

E. izixhobo zovavanyo eziyimfuneko. Ukongeza, ukulungiswa kwesikhunta kufuneka kulandele inkqubo engqongqo kwaye kuxhomekeke kubasebenzi abakumgangatho ophezulu ukuba basebenze.

(4) Ukukhetha umatshini ziphene yokubumba

Izixhobo ziphene yokubumba iindawo zeplastiki ngqo eliphezulu.

A. kufuneka usebenzise ngqo umatshini ziphene sukube kungekho ngaphezu kweminyaka emi-5 yobomi benkonzo.

Imeko-bume yefektri icocekile kwaye icocekile.

C. iindawo ultra-ezingcakacileyo, kufuneka kubekho-high speed-ziphene umatshini yokubumba.

D. umbala ophindwe kabini okanye iinxalenye ezingangeni manzi kufuneka zibe noomatshini bokufaka inaliti yokubumba.

Inkqubo yesandi yoqinisekiso lomgangatho

(5) ukupakisha iindawo zeplastiki ezichanekileyo

Ukupakisha okuhle kubalulekile ukuthintela ukukrwela, ukukhubazeka, uthuli kwezothutho, ukugcinwa kweeplastiki ezichanekileyo.

A. iindawo eziphezulu ezibengezelayo mazincanyathiselwe nefilimu ekhuselayo.

B. iinxalenye ezincinci ezibiyelweyo mazisongelwe kwiipokotho okanye igwebu elikhethekileyo, okanye lahlulwe ngemela lephepha ukunqanda uxinzelelo ngqo.

C. Iinxalenye ekufuneka zithuthwe umgama omde akufuneki zibekwe ngokukhululekileyo kwiibhokisi. Iibhokisi ezininzi kufuneka zilungelelaniswe ngokudibeneyo kunye noonogada.

Inkampani yeMestech inoomatshini kunye nezixhobo zokwenza imveliso yokubumba yeplastiki kunye nenaliti yokubumba. Siyathemba ukuba uza kukunika ulwenziwo kunye neenkonzo imveliso iindawo zeplastiki ngqo.